Join Our Webinar

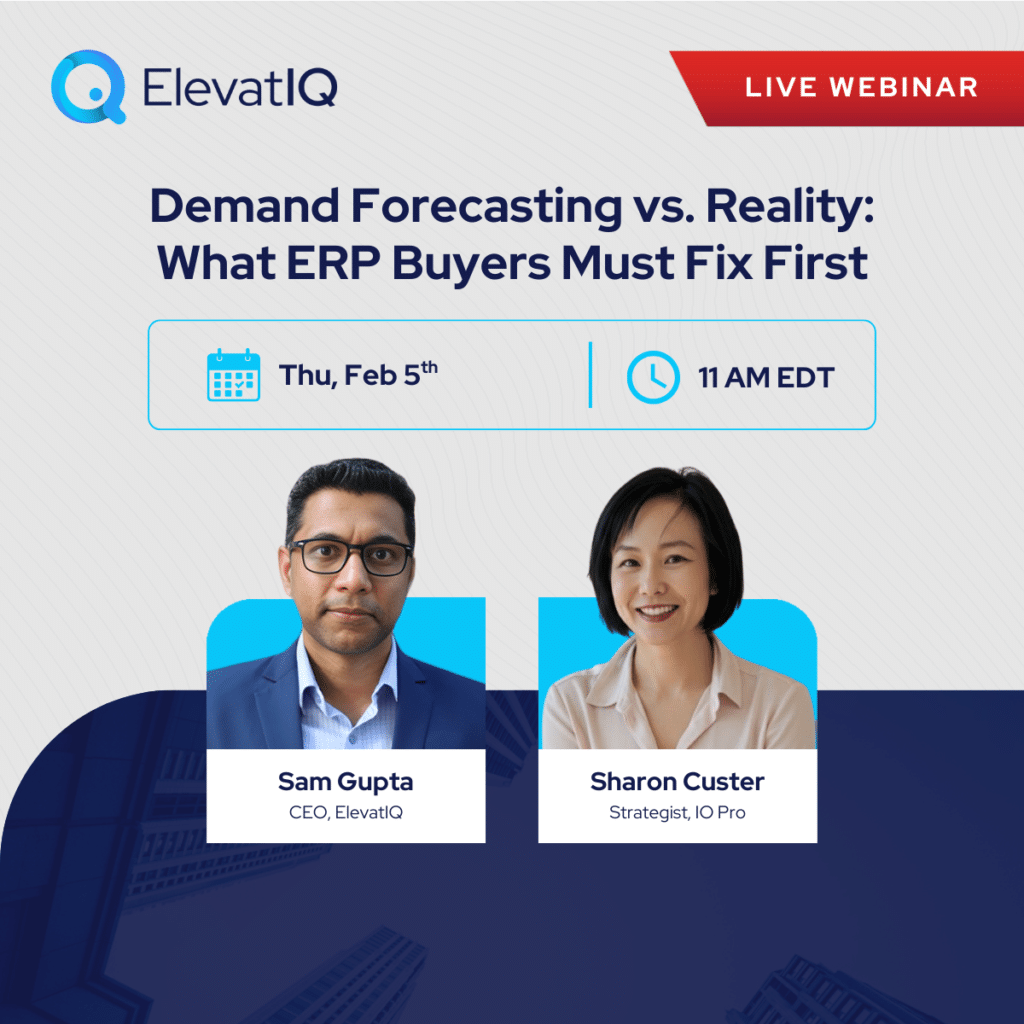

Demand Forecasting vs. Reality: What ERP Buyers Must Fix First

Feb 5th, 2026 | 11 AM ET

Most companies blame their demand forecast when they face stockouts or excess inventory. That sounds logical. It is also incomplete. In reality, most “forecast problems” are policy problems in disguise. Fix the rules, and the forecast suddenly looks smarter—without changing the model.

This webinar reframes demand forecasting from a systems perspective. Instead of chasing better algorithms, we focus on the operational, organizational, and data issues that quietly sabotage forecast accuracy. You will learn why inaccurate actuals, broken incentives, poor master data, random safety stock rules, and weak governance create more volatility than any statistical method ever could.

Through practical examples, we break down 20 common structural issues that distort demand signals. Topics include product lifecycle blind spots, promotion and pricing effects, lead-time assumptions, warehouse network design, returns handling, channel math, and near-term signal neglect. Each topic connects directly to real-world stockouts and overstock situations.

You will leave with a clear framework to diagnose root causes, redesign policies, and align teams around reality-based planning. This is not a theory session. It is a playbook for building a forecasting environment that actually works.

Register to save a spot today!

Learning Objectives:

Join Now

Identify why most demand forecast failures are driven by policy, not math.

Diagnose how inaccurate actuals and broken master data corrupt forecasts.

Align incentives so teams stop bending demand numbers.

Incorporate promotions, pricing, and product lifecycles into planning logic.

Replace random safety stock rules with structured, defensible policies.

Avoid averaging lead times in environments with real variability.

Improve allocation decisions when inventory is scarce.

Fix governance gaps that undermine otherwise good forecasting methods.

Measure forecast accuracy where it actually matters to the business.

Shift from single-number planning to range-based decision models.

Account for warehouse network effects on perceived demand volatility.

Integrate near-term signals into operational planning cycles.

Correct channel math and returns distortions.

Design organizational structures that support forecast accuracy.

Build explainable forecasting processes that enable continuous improvement.

Speakers

Sharon Custer

Inventory Optimization Strategist | Inventory Optimization Pro

Sharon Custer is an inventory optimization advisor. She works with business owners and CFOs to hold purchasing decisions before they harden into POs that are expensive to unwind. She helps businesses that carry inventory, whether they sell products or deliver projects, reduce working capital pressure, protect service levels, and improve margin credibility.

Sam Gupta

CEO | ElevatIQ

Sam Gupta has been a thought leader in the digital transformation space for nearly two decades, with the primary focus on business software. Sam is rated as #1 thought leader in the ERP and CRM categories and #5 in the digital transformation category on Thinkers 360. He is also among the top 100 thought leaders across all categories. He has been part of large transformation initiatives for Fortune 500 corporations, but now spends his time consulting with SMEs as a CEO at ElevatIQ. Sam regularly speaks at industry conferences and contributes his experiences through many popular blogs and publications. He also hosts a podcast called WBSRocks, focused on business growth through digital transformation, where he interviews top influencers and executives focused on digital transformation.