SYSPRO research indicates that while manufacturers around the world are increasingly interested in adopting smart manufacturing technologies, many are encountering considerable obstacles in their path to deployment. The study explores the current landscape of digital transformation in manufacturing, finding that despite enthusiasm for AI, automation, and IIoT, companies are often held back by internal limitations such as outdated systems, poor data accessibility, and workforce shortages.

Breaking Down the Key Insights

Smart Manufacturing Gains Momentum

Insights from SYSPRO research show that a growing number of manufacturers have already started incorporating advanced technologies into their operations:

- 37% have rolled out automation and robotics.

- 19% have adopted artificial intelligence or machine learning.

- 18% are leveraging the Industrial Internet of Things (IIoT).

Looking ahead to 2025, SYSPRO research finds that the top three focus areas are investment in AI and automation (40%), enhancing digital integration for real-time decision-making (29%), and using technology to reduce costs (24%).

China Takes the Lead in Adoption

SYSPRO research also underscores regional disparities, noting that nearly 45% of Chinese manufacturers have already embraced emerging technologies. This positions China ahead of North America and Europe, reflecting both stronger policy support and faster tech implementation on the ground.

AI Is Gaining Ground, but Rollout Remains Limited

While the interest in artificial intelligence is evident, SYSPRO research reveals that only 12% of companies have fully deployed AI systems. A further 57% are currently in the exploration or evaluation phase, and 11% expect to begin implementation within the next year. In total, nearly 80% are engaging with AI in some form, pointing to its rising importance across the industry.

Deployment Faces Operational Barriers

Despite clear momentum, actual ERP implementation continues to be a hurdle. According to SYSPRO research, 30% of manufacturers cite challenges with integrating new technologies into legacy systems. Another 15% are constrained by outdated infrastructure, while a separate 15% point to issues with scalability.

Data and Analytics Still Lag Behind

The report also draws attention to persistent data-related challenges. SYSPRO research notes that 40% of surveyed manufacturers lack access to real-time operational data, while 24% are not currently using any form of analytics. Only 23% have made analytics a near-term priority, suggesting this area remains underdeveloped for many.

Workforce Readiness Is a Growing Concern

One of the recurring themes in SYSPRO research is the shortage of qualified personnel. Around 30% of respondents report difficulty in sourcing talent with the skills needed to support advanced technologies. Additionally, concerns around supply chain stability (23%) and cybersecurity risks (12%) continue to affect confidence in the pace of digital change.

Common Questions We Are Hearing

- Is now the right time to invest in AI and smart tech? A common concern among buyers is whether they risk falling behind by waiting. Based on SYSPRO research, although widespread deployment is still limited, most companies are preparing for AI adoption, making the current moment a critical planning phase.

- Can small and mid-sized manufacturers afford digital transformation? The upfront costs can be high, prompting questions about ROI. SYSPRO research suggests that financial incentives, such as phased rollouts or external funding, may be essential for smaller firms to keep pace.

- Are legacy ERP systems compatible with new smart technologies? Integration is a major issue. As SYSPRO research shows, many organizations are held back by rigid or outdated systems that don’t support easy incorporation of advanced tools.

- How important is workforce training in successful implementation? SYSPRO research clearly points out that technology alone isn’t enough. Upskilling the workforce is seen as critical to ensuring these investments translate into productivity and performance gains.

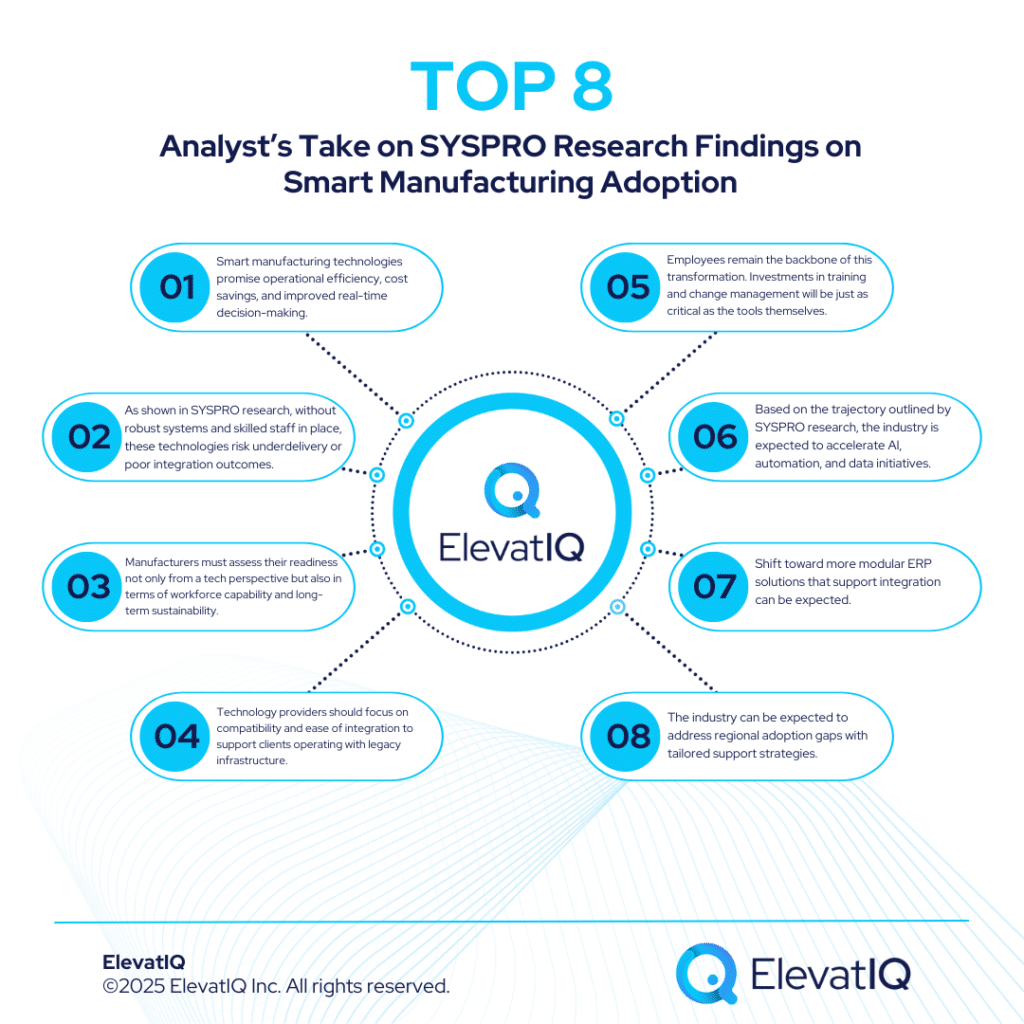

Analyst’s Take on SYSPRO research Findings

The findings of SYSPRO research reflect a manufacturing sector that is eager to evolve but grappling with deeply embedded challenges. The data points to a transitional period, marked by bold plans, cautious steps, and an urgent need for infrastructure and workforce alignment.

Merits and Demerits

- Merit: Smart manufacturing technologies promise operational efficiency, cost savings, and improved real-time decision-making.

- Demerit: As shown in SYSPRO research, without robust systems and skilled staff in place, these technologies risk underdelivery or poor integration outcomes.

Stakeholder Implications

- Manufacturers must assess their readiness not only from a tech perspective but also in terms of workforce capability and long-term sustainability.

- Technology providers should focus on compatibility and ease of integration to support clients operating with legacy infrastructure.

- Employees remain the backbone of this transformation. Investments in training and change management will be just as critical as the tools themselves.

Future Outlook

Based on the trajectory outlined by SYSPRO research, the industry is expected to:

- Address regional adoption gaps with tailored support strategies.

- Accelerate AI, automation, and data initiatives.

- Expand investments in digital skill development.

- Shift toward more modular ERP solutions that support integration.