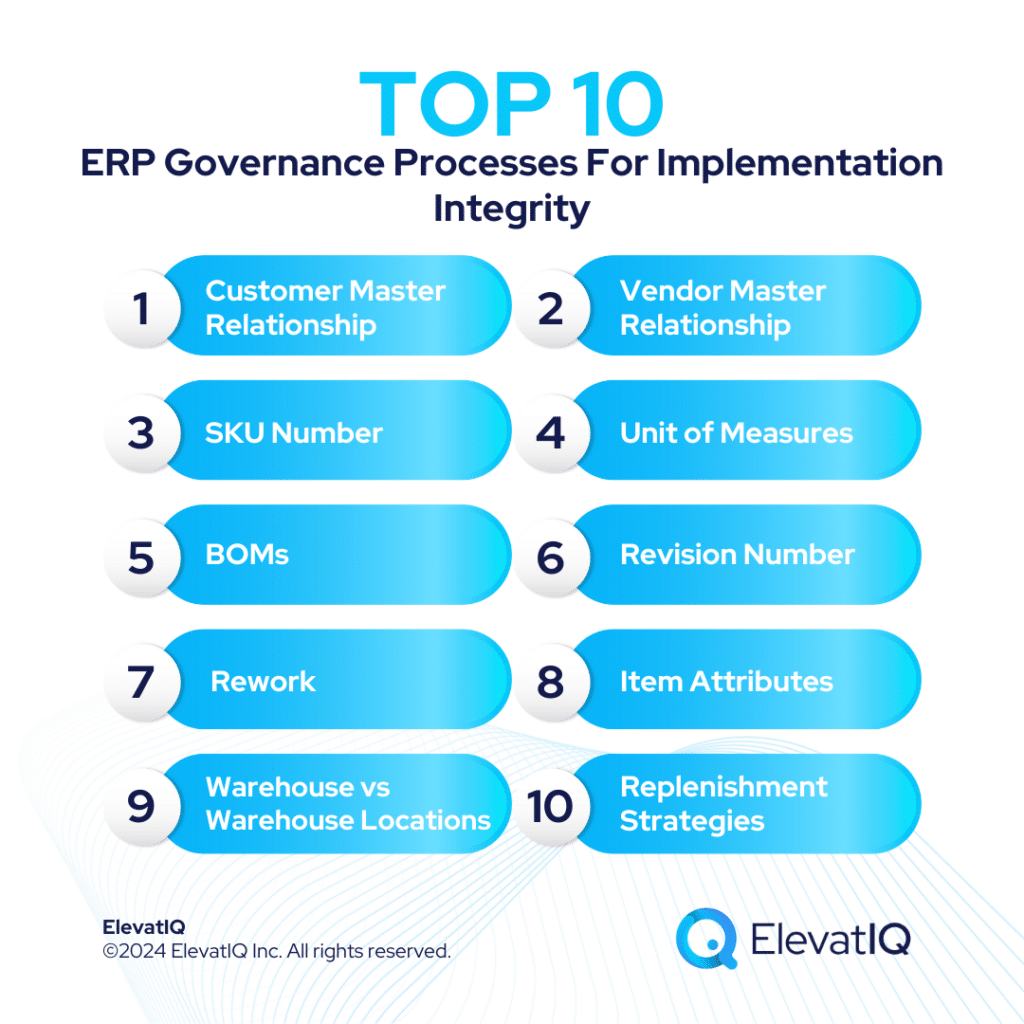

ERP is a powerful technology, but it’s generally not one system for all your problems. Even if you have a state-of-the-art ERP selection and ERP implementation, you might still run into issues unless you have the ERP governance processes. So, what are the top 10 ERP governance processes that maintain ERP implementation integrity?

Commonly, companies approach ERP implementation and ERP selection with the belief that hiring consultants will suffice to navigate the complexities of the new system. They anticipate a smooth implementation process with a minimal strategy selection phase and post-implementation involvement. They might also think that once the implementation is done, they might not need guidance from the consultants.

However, this approach might pose challenges, especially in managing internal operations without well-defined ERP governance processes or a center of excellence overseeing master data governance. Without proper ERP governance processes, even the most advanced implementation might run the risk of derailment due to data inconsistencies.

10. Replenishment Strategies

Make-to-order vs Make-to-stock. Traditional replenishment strategies, such as make-to-order vs make-to-stock, could have a substantial impact on your ERP selection and implementation. Just because you have structured your processes as make-to-order and are able to run your business fine with this strategy doesn’t mean that it would be an optimal strategy for your future implementation. These configurations could also vary per product category. Companies, with poorly implemented ERP systems, struggle to differentiate between such strategies, leading to misconfigurations based on a limited understanding of the system.

Implications of Mix-up. The distinction between strategies such as make-to-order and make-to-stock isn’t always clear-cut, often resulting in grey areas. Mixing these approaches can cause issues with lead times, process tracking, and lead time calculations by the system, necessitating numerous modifications and extra steps to achieve accurate planning before releasing production orders.

Process Governance Meaningful Even Post Implementation. Effective ERP governance processes for replenishment strategies are essential, even post-implementation. Clear guidelines must be established for setting up product data, replenishment algorithms, and SKU correlation with the warehouse. Without proper governance, a multitude of issues may arise, impacting operational efficiency and overall performance.

9. Warehouse vs Warehouse Locations

The Blurred Lines of Physical and Digital Operations. This requires a deeper understanding of the ERP data model. While some companies grasp it, others may not, leading to a mix-up in interpretation among users. This confusion often extends to distinguishing between a warehouse and a warehouse location.

Implications of this Mix-up. Such ambiguity can cause significant planning challenges. Therefore, clear ERP governance processes defining what constitutes a warehouse and how it is defined are essential. Additionally, confusion might also arise when labeling something as a warehouse without it being a physical facility. Given these complexities, sound judgment is necessary. Without clear guidelines on warehouse definition and identification, even a state-of-the-art ERP implementation may encounter issues post-implementation.

8. Item Attributes

They are like Sugar, Requiring Judgment. Item attributes often cause issues, especially when there are unclear guidelines regarding what constitutes an attribute and how to incorporate details into the item model. Within ERP systems, distinguishing between attributes and non-attributes is often a delicate matter, with implications for planning, costing, and integration with other systems.

Implications of this Mix-up. Therefore, ERP governance processes for item attributes are crucial, defining what qualifies as an attribute and when to consider it, particularly during product launches. While determining whether something is an attribute can be challenging, clear guidelines are essential to avoid potential problems. Without such guidelines, issues are likely to arise.

7. Rework

Shortcuts aren’t as Clever with Rework. Rework is a significant process within production, and its handling should ideally be straightforward. However, companies often encounter challenges when incorporating rework into their BOMs. When rework is inconsistently labeled as a routing step or explicitly identified as rework across different processes, it can lead to numerous issues throughout production and procurement.

Implications of this Mix-up. To mitigate these challenges, ERP governance processes surrounding rework are crucial. Defining rework clearly and consistently is paramount. Establishing documented workflows, ensuring compliance, and implementing approval processes specific to rework can significantly enhance the integrity of ERP implementations.

6. Revision Number

The Subtle Art of Mastering Revision Numbers. The management of revision numbers within your data model can vary significantly. Sometimes revisions are recorded separately, while other times multiple names may be included within a single revision number. Additionally, the handling of revision numbers may depend on the user’s level of expertise with the products being used. This underscores the importance of training, compliance, and governance. It’s essential to monitor how teams handle this aspect, especially for new hires, for at least six months.

Implications of this Mix-up. Clear guidelines regarding when to use revision numbers are crucial. Implementing control workflows and restricting access to individuals who are more knowledgeable about the ERP system can prevent many headaches. However, mishandling revision numbers often leads to integrity issues during ERP implementation. Therefore, ERP governance processes surrounding revision numbers are paramount to ensure the system functions effectively and accurately reflects the organization’s data.

5. BOMs

The Bill of “Migraines.” BOMs drive numerous governance issues, particularly in defining work orders versus routing steps, or distinguishing between engineering BOMs and production BOMs. These issues can significantly impact the integrity of ERP implementation. Maintaining this integrity is crucial, regardless of whether it’s been six months or a year since implementation.

Implications of this Mix-up. Control over these aspects must always be upheld once BOMs are integrated into the recall process. Once they’re transferred to customers, who may utilize serial numbers, altering the BOM’s state becomes challenging. Hence, clear guidelines on ERP governance processes surrounding BOM design and workflows are extremely critical for maintaining ERP implementation integrity.

4. Unit of Measures

The Unpleasant Toll of Misconfigured UoMs. Unit of measures significantly influences various aspects. Sometimes, companies might not prioritize units of measures adequately. They might organize them as separate SKUs or incorporate them as drop-down options on forms, as that aligns with technical understanding of requirements. However, unit of measure necessitates modeling data according to its structure and how units are procured, consumed, and sold.

Implications of this Mix-up. Proper modeling is crucial; failure to do so or to maintain ERP implementation integrity can lead to adverse effects. Mixing these schemes will likely result in planning and scheduling issues wherever these units of measures are utilized. Thus, ERP governance processes surrounding unit of measures are important for maintaining ERP implementation integrity.

3. SKU Number

Intelligent SKUs aren’t as intelligent. Clear guidelines regarding SKU numbers are essential. Opting for autogenerated SKU numbers is typically the best approach as it simplifies maintenance. Autogenerated SKUs eliminate debates about what can or cannot be included in the SKU number. Legacy systems may not support automated SKU generation, or if they do, the utility might not be seamlessly integrated with SKU numbers.

Implications of this Mix-up. This disconnect can lead to issues, especially if an external add-on or utility is used for generation but cannot enforce SKU numbers on the product master itself. Additionally, modeling SKU numbers to accommodate variance in configurable inventory can pose challenges. Thus, ERP governance processes over SKU numbers are crucial for post-ERP implementation integrity.

2. Vendor Master Relationship

New Hand, New Version of the Same Vendor. You’ll encounter numerous challenges regarding vendor master relationships, as they are frequently updated. Unlike unit of measures or item attributes, which may not undergo frequent changes, the vendor master data is subject to frequent updates, especially considering the number of vendors involved in the process. Many individuals are responsible for maintaining vendors and may argue that centralized control slows down their operations. However, granting them control can lead to inconsistencies and break the implementation’s integrity.

Implications of this Mix-up. Common issues arise regarding how shipping tools and vendors are captured, sometimes resulting in confusion between ship-to addresses and vendor details. Additionally, decisions regarding whether vendors also serve as customers or employees impact ERP planning. Therefore, implementing ERP governance processes for vendor setup is essential to ensure smooth operations.

1. Customer Master Relationship

Customer Master is as Crucial as Your Customers. Similar to vendor master data, customer master data encounters comparable challenges, with complexity varying depending on the organization’s specific circumstances. Some companies may have millions of customers but fewer vendors, while others may have the opposite scenario. Regardless, complexity of both customer and vendor master data influences operations. Issues arise when incorporating buying groups into the customer master model, especially if assumptions are made without aligning with the ERP data model, leading to planning complications.

Implications of this Mix-up. Sometimes, issues may not manifest immediately, potentially going unnoticed during testing. Overlooking consultant advice on setup complexity can exacerbate issues later on. Despite consultants recommending a certain setup, some organizations may perceive it as overly complicated and opt for a simpler approach, only to encounter issues afterward. Therefore, careful consideration and alignment with ERP data models are essential to avoid complications down the line.

Conclusion

In conclusion, while ERP technology offers immense potential for streamlining operations, its successful implementation requires more than just cutting-edge software and consultants’ expertise. The governance processes surrounding ERP systems, including master data management and operational protocols, are paramount for maintaining implementation integrity. The top 10 ERP governance processes highlighted in this blog underscore the importance of clear guidelines, consistency, and alignment with organizational needs and ERP data models.

Whether it’s managing vendor and customer master relationships, defining SKU numbers, or ensuring accuracy in unit of measures and BOMs, robust ERP governance processes are essential for mitigating risks and ensuring smooth operations post-implementation. Without these governance mechanisms in place, even the most advanced ERP systems are susceptible to data inconsistencies, planning challenges, and operational disruptions. Therefore, organizations must prioritize establishing and adhering to ERP governance processes to maximize the benefits of their ERP investments and drive long-term success. While this blog provides helpful insights, consulting an independent ERP consultant can significantly improve your implementation outcomes.