Make-to-order Companies: In the vast realm of manufacturing, make-to-order companies stand out with their distinct operations. Often grouped alongside make-to-stock, engineer-to-order, and project manufacturing, make-to-order firms operate uniquely. Unlike make-to-stock businesses, they craft products upon order placement, necessitating specialized supply chain processes. While similar to engineer-to-order setups, make-to-order companies typically require less customer interaction and tackle less intricate engineering challenges.

Make-to-order Manufacturing Business Processes: To grasp the dynamics of make-to-order processes, consider the distinction between one-off and planned needs. One-off needs, such as unique machine parts, often drive this approach, catering to specialized requirements. Additionally, factors like product cost and lead time urgency influence whether a product falls under make-to-order or make-to-stock categories. Typically, expensive products favor make-to-order to preserve cash reserves, while urgent customer demands may prompt some make-to-order items to transition to make-to-stock for enhanced service delivery.

Make-to-order Manufacturing ERP Needs. Make-to-order businesses require unique SKU strategies, often tailored to their specific processes. Unlike engineer-to-order enterprises, where make-to-order processes might also be required for their parts business, standalone make-to-order firms operate with simpler structures, fewer long-term projects, and reduced planning needs, simplifying the need for mixed-mode manufacturing. Their billing and financial planning requirements are also less complex. Additionally, managing the ecommerce component poses challenges, as it involves configurator processes due to less formalized SKUs, although not as ad-hoc as engineer-to-order setups. Now, let’s explore the top make-to-order manufacturing ERP systems for 2024.

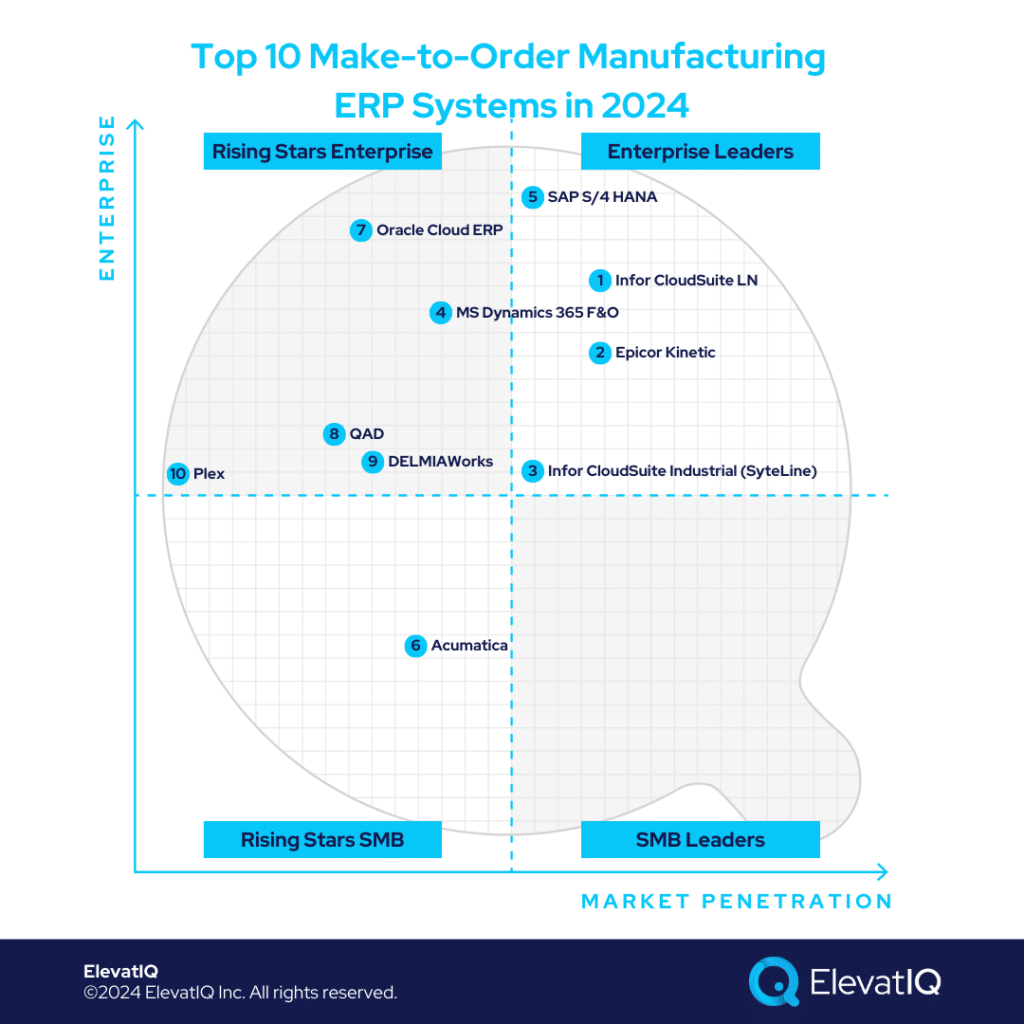

Criteria

- Definition of a make-to-order manufacturing company. These companies in the make-to-order ecosystem include manufacturers primarily following make-to-order business mode in a variety of industries, including automotive, aerospace, plastics, and building materials etc. The list considers companies of all sizes in this ecosystem.

- Overall market share/# of customers. The higher marketshare among make-to-order companies drives higher rankings on this list.

- Ownership/funding. The superior financial position of the ERP vendor leads to higher rankings on this list.

- Quality of development. How modern is the tech stack? How aggressively is the ERP vendor pushing cloud-native functionality for this product? Is the roadmap officially announced? Or uncertain?

- Community/Ecosystem. How vibrant is the community? Social media groups? In-person user groups? Forums?

- Depth of native functionality. Last-mile functionality for specific industries natively built into the product?

- Quality of publicly available product documentation. How well-documented is the product? Is the documentation available publicly? How updated is the demo content available on YouTube?

- Product share and documented commitment. Is the product share reported separately in financial statements if the ERP vendor is public?

- Ability to natively support diversified business models. How diverse is the product in supporting multiple business models in the same product?

- Acquisition strategy aligned with the product: Any recent acquisitions to fill a specific hole for make-to-order industries? Any official announcements to integrate recently acquired capabilities?

- User Reviews: How specific are the reviews about this product’s capabilities? How recent and frequent are the reviews?

- Must be an ERP product: Edge products such as HCM, CRM, eCommerce, MES, or accounting solutions that are not fully integrated to support enterprise-wide capabilities are not qualified for this list.

10. Plex

Adopting an MES-first strategy, Plex targets companies in the Toyota and Ford automotive ecosystems. Despite superior technology compared to other solutions on this list, Plex has fewer installs, primarily focusing on the automotive industry. The automotive industry, especially the large OEMs, where Plex is especially known, are generally made-to-stock, requiring joint collaboration with their suppliers, which might be overkill for simpler made-to-order businesses. Plex secures its rank at #10 among the top make-to-order manufacturing ERP systems by emphasizing more operational capabilities than the core ERP needs, thus making it an ideal fit for MES-heavy make-to-order manufacturers, especially in the automotive ecosystem.

Strengths

- Last-mile functionality for Toyota and Ford ecosystems. Tailored for manufacturers in the Toyota ecosystem (i.e., Toyota suppliers), Plex offers distinctive features, especially the compliance requirements that would require substantial consulting efforts on vanilla ERP systems.

- MES-first approach. Originating as an integrated MES solution, Plex boasts extensive MES capabilities. This appeals to make-to-order companies handling processes traditionally within ERP, like quality, scheduling, and asset maintenance, providing a valuable shop floor perspective.

- Cloud-native UI and architecture. Similar to cloud-native alternatives like Acumatica or NetSuite, Plex features a cloud-native and mobile-friendly user interface.

Weaknesses

- Limited core ERP capabilities. While Plex lacks extensive finance and accounting capabilities for global organizations, it could be a great two-tier solution used at the plant level on top of Oracle and SAP as a corporate system.

- Limited make-to-order manufacturing capabilities. While it might have some make-to-order capabilities, it might not be the best fit for make-to-order manufacturing companies requiring mixed-mode manufacturing capabilities.

- Limited ecosystem and consulting base. Plex has fewer installations and a minimal marketplace and consulting base compared to other manufacturing ERP systems on this list.

9. IQMS/DELMIAWorks

IQMS, tailored for plastics-centric operations, would be uniquely suitable for plastic extrusion make-to-order manufacturing companies working for large OEMs in the automotive and aerospace verticals. These companies generally have unique workflows, such as maintaining SDS for each client and meeting their quality requirements. Enabling these capabilities on top of vanilla ERP systems might require substantial consulting efforts. IQMS would be an ideal fit for smaller make-to-order companies or for larger companies as a subsidiary-level system, thus contributing to its placement at #9 among make-to-order manufacturing ERP systems.

Strengths

- Great for plastic-extrusion make-to-order manufacturers. While limited in its suite, capabilities for plastic-centric make-to-order industries outshine when it comes to unique scheduling requirements.

- Best for make-to-order companies on SolidWorks. With the same company as SolidWorks owning it, tighter and seamless integration of both products, which are built and maintained by the same vendor, is a huge plus.

- Technology – This is probably the most legacy solution of all on this list, with no announcement if they plan to modernize the technology.

Weaknesses

- Limited focus. The limited focus might be a challenge for make-to-order companies diversifying their operations and being active with M&A cycles.

- Limited ecosystem. The consulting base is extremely limited with most resellers being CAD resellers, with limited experience in ERP implementation and cross-functional processes.

- It is not the right fit for holding and private equity companies as a corporate ledger. While a great subsidiary solution and a solution for pure-play make-to-order plastic-centric manufacturers, it’s not the best fit for companies requiring diverse mixed-mode manufacturing companies or companies with complex business models.

8. QAD

With QAD’s focus being primarily on mid-to-large automotive, electronics manufacturing, and life sciences companies, its scope for make-to-order companies is limited, meaning it might not be the best fit for every make-to-order business model, requiring careful evaluation. It might also not be the best fit for companies requiring mixed-mode manufacturing capabilities along with make-to-order. While they have announced plans to advance their technology stack, the new version might take a while to be fully rolled out and available, securing its rank at #8 on our list among the top make-to-order manufacturing ERP systems.

Strengths

- Global capabilities. While not as globalized and localized as other larger solutions, such as SAP S/4 HANA or Oracle, QAD is as limited as smaller solutions and can accommodate several countries with global synergies in one product/database.

- Supply chain suite + ERP. Combining capabilities that traditionally resided in a Supply Chain Suite, QAD includes trade compliance, TMS capabilities, and S&OP planning in its core solution. These capabilities are not generally as applicable for make-to-order business models but might be a great fit for companies that may have other layers in their business model along with make-to-order.

- Integrated best-of-breed capabilities. QAD offers best-of-breed integration, such as PLM and TMS, which would require substantial consulting efforts on top of other vanilla ERP systems.

Weaknesses

- Diverse business models. QAD’s limited focus poses challenges for holding and private equity companies with aggressive M&A cycles trying to keep all of their entities on one solution.

- Global corporate solution. While operationally strong, QAD may not be the best fit for companies seeking a global corporate financial solution.

- Weak ecosystem. QAD lacks a robust ecosystem, including limited partners and coverage for third-party add-ons and marketplaces.

7. Oracle Cloud ERP

Geared toward large global manufacturing firms, Oracle Cloud ERP excels with high transaction volumes, especially when Oracle Cloud ERP might be used only as a corporate financial ledger while using other specialized solutions such as Infor LN or Epicor Kinetic at the subsidiary level. Oracle Cloud ERP might have limited last-mile capabilities and integrations required for make-to-order businesses such as CAD, PLM, configurators, or MES. Oracle Cloud ERP would rely on third-party add-ons for such capabilities. Being primarily relevant for larger make-to-order companies. Thus, Oracle Cloud ERP ranks at #7 on our list of top make-to-order manufacturing ERP systems.

Strengths

- Robust finance capabilities for large, global make-to-order manufacturers. Capabilities include having five layers of GL restrictions, multiple layers of sub-ledgers, and book closing requirements across divisions, especially relevant for larger make-to-order businesses primarily interested in using Oracle Cloud ERP as a corporate financial ledger.

- Proven solution with large workloads. Large companies may process millions of GL entries per hour. These workloads may be even higher for manufacturing companies. They might need to decouple transactions as a single system might struggle to support, requiring best-of-breed architecture for such companies, an ideal fit for Oracle Cloud ERP.

- Ecosystem. Oracle Cloud ERP has an ecosystem of experienced consultants who have the capabilities to handle the design and architecture of such complex enterprises.

Weaknesses

- Limited last-mile capabilities and make-to-order integrations. The last-mile capabilities and specialized integrations relevant for make-to-order businesses might require third-party add-ons.

- Not necessarily a manufacturing solution. Oracle Cloud ERP’s concentration in make-to-order businesses is limited, making it a lower priority for make-to-order businesses.

- Overwhelming for SMB make-to-order manufacturers. The enterprise data model and financial layers might be overwhelming for SMB make-to-order manufacturers.

6. Acumatica

Tailored for manufacturing companies in the $10-100 million range, Acumatica suits make-to-order manufacturers with simpler operations. While Acumatica has BOMs and manufacturing layers required for make-to-order operations, mature ERP layers such as Kanban or allocation might be limiting compared to other richer manufacturing solutions such as Epicor Kinetic or Infor LN. However, Acumatica might be a better fit for companies with diverse make-to-order business models when they might have flavors of other business models such as eCommerce, field service, or construction. Thus, given its relevance for smaller make-to-order manufacturers, it ranks at #6 on our list of make-to-order manufacturing ERP systems.

Strengths

- Rich BOMs and scalable costing layers. Acumatica BOMs are highly organized and follow logical structure across the screens, making them highly scalable for companies with complex product models.

- Diverse capabilities to support the needs of multiple business models. The product can accommodate multiple business models in the same database, making it easier to explore synergies across different business models without requiring isolated operations for heterogeneous operations.

- Cloud-native UI and flexible pricing options. Superior experience for teams using ERP primarily on mobile devices. Consumption-based pricing options reduce costs substantially for certain business models, such as seasonal businesses with labor spikes.

Weaknesses

- Limited global capabilities. The current multi-entity functionality might be limiting for make-to-order companies with operationally connected offshore locations.

- Limited mobile reporting capabilities. The mobile capabilities are leaner for complex reporting scenarios such as parallel processing or reporting labor or machines separately from the same work center. These capabilities are highly critical for make-to-order operations.

- Multiple add-ons may be required for make-to-order manufacturing. Requires several third-party add-ons, such as MES, PLM, and quality, posing integration and communication challenges.

5. SAP S/4 HANA

Targeting large global make-to-order manufacturing companies, SAP S/4 HANA excels in handling millions of transactions per hour, a requirement for companies of Fortune 500 scale. Ideal for large publicly traded companies heavy on financial compliance and governance, it may not suit SMB manufacturing companies without internal IT maturity. SAP S/4 HANA enjoys a unique advantage for MRP-driven companies requiring enterprise-grade workloads intending to keep all of their entities in one database. Thus, ranking at #5 on our list of top make-to-order manufacturing ERP systems.

Strengths

- Enterprise product designed for make-to-order centric companies. The item master, product model, and warehouse architecture are especially friendly for make-to-order businesses because of scalable and modular BOM and costing layers.

- The power of HANA to run global operations end-to-end in one system. Our simple test of HANA’s capabilities with 100K serialized goods receipt found it to be faster than most systems out there. SAP S/4 HANA could process it in under 22 seconds, while Oracle cloud ERP took more than 18 mins for the same test. This is especially friendly for large make-to-order businesses aiming to run their consolidated global MRP runs in one system.

- Financial governance and best-of-breed architecture. Financial traceability is built with each transaction, which makes the transactions and SOX governance flows highly traceable, especially friendly for publicly-traded make-to-order companies.

Weaknesses

- Behind in cloud capabilities. While SAP has made tremendous advancements, the cloud version is still behind its on-prem variant.

- Too big for smaller make-to-order companies. Companies looking for a fully baked suite without internal IT capabilities will find it overwhelming.

- Limited last mile Capabilities and third-party pre-integrated options. The last-mile capabilities relevant for make-to-order businesses, such as CAD and PLM integration, would require third-party add-ons.

4. Microsoft Dynamics 365 F&O

Microsoft Dynamics 365 F&O excels in localizations where other focused solutions might not be available, providing only a few options for make-to-order companies. While Microsoft Dynamics 365 F&O has a very rich product model to support complex make-to-order operations, it might not have a complete suite and integrated options as focused solutions, such as Epicor Kinetic or Infor LN, requiring third-party add-ons for these capabilities. Despite being limited with suite capabilities, it will be more suitable for diverse make-to-order operations or companies with uncertain business models because of M&A activity, securing the #4 spot among the top make-to-order manufacturing ERP systems.

Strengths

- Richer core ERP capabilities for make-to-order companies in the cloud. Compared to other solutions that might have superior layers for other service-centric verticals, such as Oracle Cloud ERP, Microsoft Dynamics 365 F&O has a mature cloud version for make-to-order companies.

- Best-of-breed products integrated at the database level. While Microsoft has best-of-breed integration such as CRM or field service, they might not be as directly relevant for make-to-order companies but will be useful for make-to-order companies with diverse business models.

- Powerful ecosystem and marketplace add-ons. Microsoft has a talent and consulting base in countries where finding talent may be a challenge.

Weaknesses

- Limited pre-baked integrations for make-to-order companies. The integration relevant for make-to-order companies such as PLM, CAD, MES, and configurator would require third-party add-ons, increasing communication and integration risks.

- Too big for smaller companies. The smaller companies would find it overwhelming with the configuration and approval flows built for large enterprises.

- Limited last mile capabilities. The last-mile functionality relevant to specific industry verticals, such as PPAP compliance or AS9100, might require substantial consulting efforts.

3. Infor CloudSuite Industrial (Syteline)

Geared towards SMB make-to-order companies with extensive SKUs and complex subassemblies, Infor CloudSuite Industrial (Syteline) excels with its flexible BOM structure, accommodating both formal and informal manufacturing processes. While it has great capabilities for make-to-order operations, a complex business model requiring other mixed-mode manufacturing capabilities, such as WBS or project-centric manufacturing, might not be as detailed, securing its rank at #3 on our list of make-to-order manufacturing ERP systems.

Strengths

- Support for both informal and formal BOMs and engineering processes. Infor CSI BOMs don’t mandate a revision number, making it easier for companies with relatively unsophisticated data models and engineering processes to use without going through the painful formalization of SKUs and BOMs.

- Detailed and scalable costing layers. Compared to other products with patchy experience, the costing layers are well-designed and scale well, especially for verticals where material pricing may fluctuate, requiring frequent readjustments, such as industries dependent upon steel.

- Field service integration with the core manufacturing processes. Deep composable serviceable units are built as part of the core solution with complex assemblies and back-and-forth interactions of channels to service units in the field.

Weaknesses

- Disconnected financial reporting experience. Unlike other products, financial reports are not embedded with the product. This would require an external Excel interface, creating a patchy experience for users.

- Poor user experience and steep learning curve. While marketed as a cloud product, the cloud capabilities, such as enterprise search and opening multiple tabs, are limited. This makes the experience non-intuitive.

- Weak ecosystem and third-party options. Similar to Epicor, Infor CSI takes the suite approach. So it might be harder to find integration with best-of-breed third-party apps.

2. Epicor Kinetic

Epicor Kinetic particularly targets small-to-mid-size make-to-order manufacturers. They particularly specialize in industries with formal manufacturing processes and complex inventory needs, such as automotive, aerospace, metal, fabrication, and medical devices. Epicor is also equally deep with project-centric operations and distribution processes, making it ideal for diverse make-to-order operations. Despite recent developments, Epicor Kinetic might not be the best fit for companies with global financial operations and deep field service operations. Thus, securing its ranks at #2 on our list among make-to-order manufacturing ERP systems.

Strengths

- Strong for comapnies with formal manufacturing processes. Mandatory revision numbers and the BOMs driven by revision numbers would be especially appealing for formal engineering organizations familiar with similar formal structures.

- Strong with complex inventory needs. Companies that require multiple attributes that need to be part of the planning and MRP, such as metal, fastener, automotive, and aerospace, would find Epicor to be appealing.

- Microsoft look-and-feel. Epicor has a very similar look and feel to Microsoft ERP products. Thus, providing you with the same experience but with much deeper last-mile capabilities where other products might struggle.

Weaknesses

- Global financial operations. Unlike larger products that might support more than three layers of financial hierarchies, such as corp, subsidiary, entity, and business units, the limited number of layers would operationally inefficient workarounds, such as using sub-accounts for such traceability.

- Embedded experience with field service and quality. Despite recent acquisitions, the field service capabilities are not as embedded and proven as some of the other products on this list.

- Weak ecosystem and marketplace. Epicor takes a suite approach to its products while selling directly to its customers. This limits the overall consulting and marketplace penetration.

1. Infor CloudSuite LN

Infor CloudSuite LN is a comprehensive manufacturing solution that particularly combines the best of the most focused manufacturing solutions. While there are several solutions on this list that could be a great fit for make-to-order manufacturing, they might struggle with diverse manufacturing operations with flavors of configure-to-order, field service, and project-centric manufacturing. Besides being comprehensive, it also has make-to-order-specific last-mile capabilities and pre-baked integrations such as PLM, CAD, CPQ, and more. Thus, securing its rank at #1 position on our list of the top make-to-order manufacturing ERP solutions.

Strengths

- Global operations. Infor LN is the only solution in the market that has sufficient layers of financial hierarchies and global trade compliance functionality pre-baked with products. It supports make-to-order manufacturers exploring global financial and operational synergies.

- Last-mile capabilities along with breadth of capabilities for diversified manufacturing business models. Make-to-order verticals require deeper core capabilities that are tightly embedded as part of product and data models such as PPAP, as well as handling units, several layers of allocation management, and international trade compliance.

- Best-of-breed integrations offered out-of-the-box. Most tools that make-to manufacturer would require, such as HCM, PLM, data lake, ERP, WMS, TMS, and advanced supply chain planning, are all pre-integrated with LN.

Weaknesses

- Might not be the best fit as a corporate solution for holding and private equity companies. Holding companies as diverse as make-to-order manufacturing, construction, and professional services may not be able to keep all of their entities on one solution and database.

- Legacy UI and Experience. Infor LN is a legacy solution with limited cloud-native capabilities such as universal search, mobile experience, etc.

- Weak Ecosystem and Marketplace. The consulting base and marketplaces are virtually non-existent for Infor LN.

Conclusion

Make-to-order manufacturing stands out among other business models like make-to-stock or engineer-to-order. While key capabilities such as SKUs and BOMs are crucial, they aren’t as standardized or commercialized as in make-to-stock. However, financial processes are typically less complex compared to project manufacturing. This involves intricate revenue recognition and milestone billing for longer-term projects, unlike the relatively shorter runs in make-to-order. Thus, choosing the right ERP system for make-to-order manufacturing demands a thorough examination of transactions and processes. Also, opting for a system unsuited to this model risks implementation setbacks. While this list offers valuable insights, seeking guidance from an independent ERP consultant can greatly enhance your chances of success.