Last Updated on February 15, 2025 by Sam Gupta

While there are plenty of ERP options out there for manufacturers, most tend to be fairly generic. To fit the needs of frozen food manufacturers. If you are an SME frozen food manufacturer, all options may appear reasonably promising. But none might resonate with you. So what are the top ERP features for frozen food manufacturers?

The reason: frozen food manufacturing is unique and irrespective of how small your business might be, you need to ensure that the ERP you select supports your critical processes. Here are different frozen food segments whose business processes are typically similar. If you are one of them, read on to learn more about the critical features you would require in an ERP:

- Frozen specialty foods manufacturing: fruits and vegetables; meals; pizzas; frozen bakery products such as bread, waffles, and pancakes; gluten-free food items; snacks and bars; desserts; manufactured ice; ice creams

- Frozen pet food manufacturing: raw meals, cooked meals, packaged frozen food, kitted products, and re-packaged products.

Most popular ERP systems would probably provide the majority of the standard features. That may be enough for a ton of manufacturing companies. However, not as sufficient for frozen food manufacturers due to their specific needs.

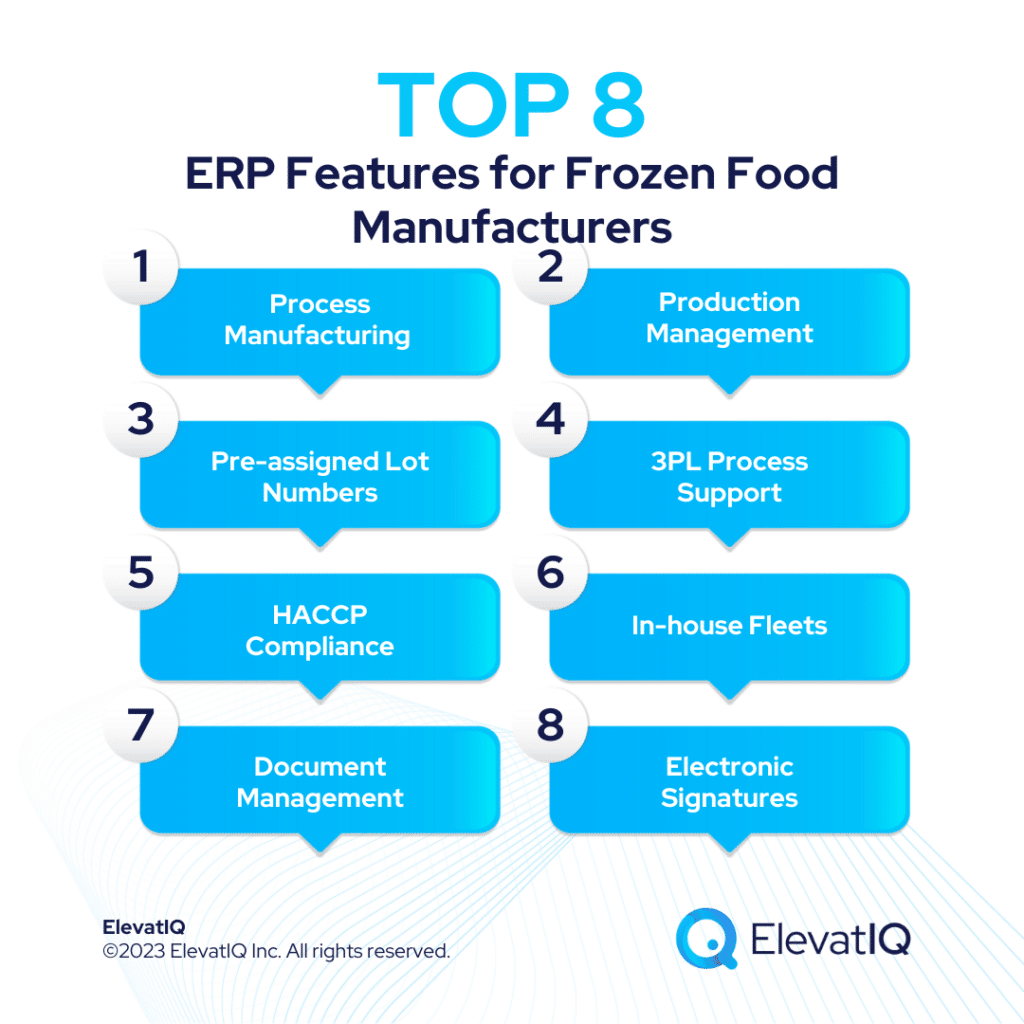

1. Process Manufacturing Management

While discrete ERP vendors might argue that there is not much of a difference between process or discrete manufacturing, that’s not true at all. Process manufacturing differs significantly, especially with their BOMs and product management processes.

The biggest difference between process and discrete would be in the structure of their BOMs (bill of material or manufacturing). Discrete manufacturing UOMs (units of measure) are relatively simpler. And the quantities of the materials don’t necessarily follow a dependency formula. On the other hand, process manufacturing formulations could be quite complex. Like a mathematical formula such as Z = 2X + Y where material Z is dependent upon the quantities of materials X and Y. While discrete manufacturing has its own challenges, the challenges related to process manufacturing don’t exist for them. This is perhaps one of the most essential ERP features for frozen food manufacturers.

2. Production Management

The process of manufacturing frozen food is complex. Similar to other F&B counterparts, you are likely to perform operations such as grinding/cutting, mixing, pouring, baking/cooking (if you are in the cooked-food segment), quality control, and packaging as part of your shop-floor operations. However, you may have additional steps, such as blast-freezing or thawing. As well as temperature-controlled picking, packing, and shipping. These operations could pose unique operational challenges to frozen-food manufacturers. Such as long-standing processes due to blast freezing, segregation of batches on the production line, etc.

The other production challenges could include having a two-step production process where part of the process is formulation-centric to prepare a batch of a base. The other part is the packaging of the base in different product configurations, similar to discrete processes. An ERP that can’t support both formulation and discrete processes simultaneously may not be sufficient for a frozen food manufacturer.

3. Pre-assigned Lot Numbers

While the lot-control feature is required in many industries, these requirements are unique to frozen food manufacturing. Why? Due to the need for recall management as well as HACCP compliance. There are very few ERP systems out there that would have features such as pre-assigned and intelligent lot numbers. If the pre-assigned lot numbers are not supported by the ERP system, your end-to-end traceability is likely to fail. Why? Due to the mixing of batches or the manual tracking of lots on the production line. In addition, the manual process might require printing a temporary number (which may not be recognized in the system)–defeating your automation and traceability goals.

4. 3PL Process Support

Most frozen food businesses also use a 3PL frozen storage facility. Because building the same capacity as part of the production site is challenging and expensive. Also, since the shipping of frozen raw materials is expensive, you might not be able to capitalize on vendor discounts if you solely relied on your internal warehouses. If your 3PL vendor allows you to use your ERP system for them to receive the goods, allocate lot numbers, and assign expiry dates, one option could be to treat your 3PL warehouse as just another warehouse.

However, 3PL warehouses are typically large. And it’s hard for them to accommodate the preferences of every customer due to the training and management overhead. Because of this issue, you require an ERP system that supports the 3PL processes natively. And a consultant like ElevatIQ who understands this space deeply to help with these unique challenges.

5. HACCP Compliance

If you plan to attain Hazard Analysis and Critical Control Points (HACCP) certification for your products, the Food Safety Modernization Act (FSMA) requires you to develop and implement an HACCP plan to address food safety by analyzing and controlling several hazards, including biological, chemical and physical. The plan must be comprehensive to include all processes, starting from the traceability of the origin of raw materials. And their production, procurement, and handling. To production, distribution, and consumption of finished goods.

HACCP aims to minimize the negative consequences associated with the release of contaminated products to consumers as well as with their recall. This requires companies to incorporate thorough quality processes across the enterprise along with a material review board. HACCP also drives the need for detailed documentation due to audits and reporting. Unless the ERP has a built-in quality management module designed to cater to the needs of the frozen food business, complying with HACCP is nearly impossible. This compliance also requires a comprehensive document management system to record, implement, and monitor standard operating procedures (SOPs). As well as support for both forward- and backward traceability to attain end-to-end traceability management goals,

Finally, HACCP requires your suppliers to be audited and the records about their performance to be maintained. So, only the highest quality raw materials are consumed through the process. The ERP solution for frozen food must support the audit and performance recording of suppliers. This is among the top two essential ERP features for frozen food manufacturers.

6. In-house Fleets

It’s very common for frozen food manufacturers to maintain their own in-house fleets, as the 3PLs might not carry their load due to their MOQ requirements. They might also struggle to work with 3PLs due to the unique requirements of how frozen food needs to be distributed. The frozen can’t stay out for a very long time. So, they have unique requirements for route planning. As well as how much load each truck might be able to carry.

7. Document Management

The document management needs are not only applicable to HACCP needs. They may need them for managing versions of their packaging and marketing materials. As well as any documentation required to maintain quality and compliance.

8. Electronic Signatures

The solution must also support record keeping and electronic signatures if you may be carrying food and beverage products where you might need to comply with the FDA-compliant inspections.

Conclusion

In conclusion, process manufacturing is hard. Frozen food manufacturing, with the added burden of compliance, is even harder. Having a consultant who has a mastery of the nuances of frozen food manufacturing and a system that supports your critical processes is vital to selecting the right ERP for your business and its successful implementation.