Document Management: A Need for Manufacturing ERPs

Manufacturers have varying document management maturity levels. Some manufacturing companies have well-defined processes for managing their documents, while others struggle with their ad-hoc procedures. Although you might manage to collaborate using ad-hoc methods, they are also a leading cause of team-related conflicts.

This article will help you understand ERP document management and its features to streamline communication and avoid any conflicts in your team.

What is ERP document management?

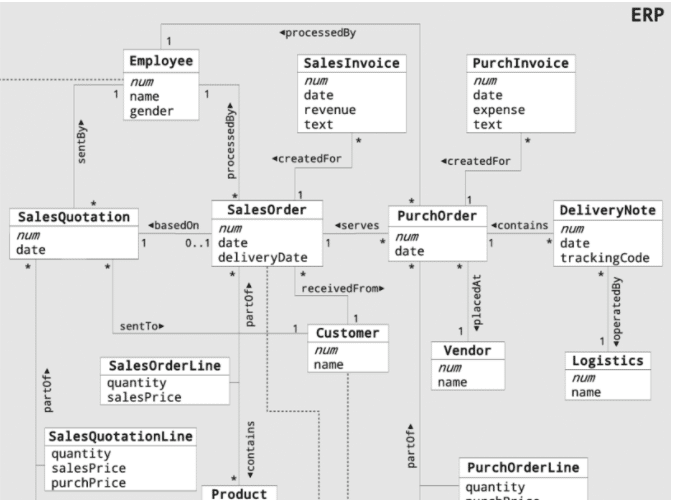

ERP document management refers to a centralized repository system to maintain all your digital and scanned documents. There could be several reasons why the documents need to be stored, including regulatory or audit. While needs vary across businesses, ERP document management system generally stores the following documents:

- Invoices, dunning letters, and printed checks

- Design documents and drawings

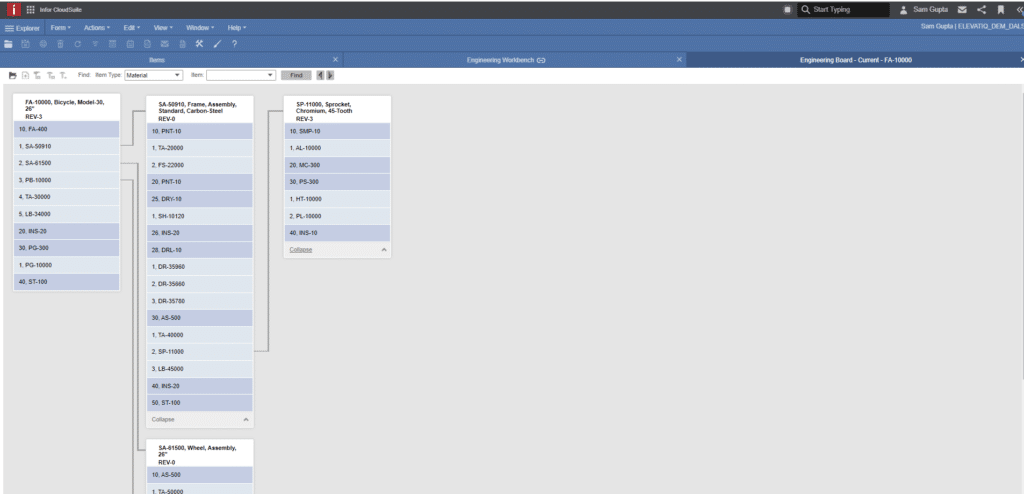

- Bill of materials and their versions

- Packaging and marketing assets

- Legal documents and contracts

- Product images from vendors and manufacturers

- Financial reports and account statements

Most functions in a company need an electronic document management system (EDMS), including sales, operations, marketing, legal, and engineering. Since their use is so wide-spread in various departments, companies also refer to it as an Enterprise Document Management system.

Options for electronic document management system

Depending upon your business processes’ maturity, these are the methods that companies use to store their documents.

1. Manual Document Management

This method does not utilize any document management software tool to store documents but keeps them in their physical form. Generally, local computers and shared drives would act as the primary storage in this method.

If you opted for this method, you might experience serious control issues due to the lack of centralized storage and governance processes.

2. Cloud-based Document Management Software

The only difference between manual and cloud storage methods is the type of storage used, with Dropbox or OneDrive being some of the choices. While this method helps prevent data loss and provides portability across devices, it would struggle with control and compliance issues.

3. Standalone Document Management System

Standalone document management software, such as Microsoft SharePoint, is the primary storage method in this method. This method solves challenges such as compliance and control; however, it will not tightly integrate with your transactions.

Therefore, you will spend a significant amount of time entering details to correlate your documents with transactions through an ad-hoc naming strategy. Additionally, this scheme’s ad-hoc nature will lead to non-compliance and challenges of finding documents quickly without manual collaboration.

4. ERP Document Management System

ERP document management consists of two significant databases or components. The first component is the document storage that stores documents in the binary format. The other part stores the contextual information, also known as metadata, that helps you correlate documents with their transactions to help find easily. This metadata will also help you implement scenarios such as bundling and consolidation of documents.

In summary, manufacturing companies could be at different maturity levels but would use one of the above methods. Most start-up companies would start with manual tracking or perhaps replace that with spreadsheets. As they grow, their needs will change. First, They might replace manual methods with cloud storage or standalone systems. Once they have outgrown their siloed systems such as QuickBooks or MISys, they will need an ERP document management system.

Six Reasons why manufacturers need ERP document management

Manufacturers, in particular, require a sophisticated records management system due to their needs for access control and the complexity of their processes. For example, if you are in the advanced manufacturing space such as Robotic Process Automation or Machinery, you may have several levels in your BOM. Each level will have a different workflow and control needs as you collaborate with your customers or suppliers.

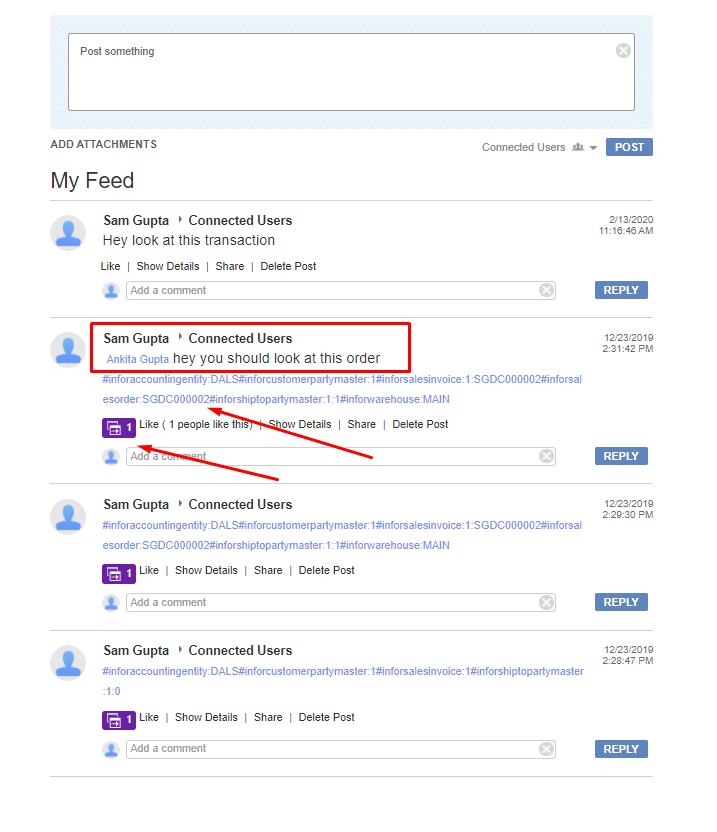

1. Collaboration

You might need to share tons of documents irrespective of whether you collaborate with your customers or communicate internally. If you use DropBox or SharePoint methods that lack the transactional correlation, the documents will likely get mixed. This mixing of documents and ad-hoc approaches may result in financial losses.

For example, if your supplier delivers the wrong part because of the incorrect design version you shared, the supplier may have to charge you for your lack of diligence. While losses with customers or vendors might be noticeable, the wastes with your internal teams may go unnoticed.

To illustrate the internal problem further, if you shared a wrong version with your production team, they might end up doing a production run for an incorrect part or spend time configuring the incorrect tooling. Most companies consider employees’ lack of training or attitude to be the cause of such conflicts. In reality, it’s the lack of a centralized document management system that automates these processes without requiring to think about them.

2. Control

When it comes to a wide variety of documents ranging from sales quotes to confidential documents, you need appropriate access levels for each stakeholder. You might argue that document management software such as SharePoint or DropBox provides robust control features.

The issue, though, with such systems is the decentralization of your control. In other words, having more than one command of authority would be an issue unless both sources refer to the same database. In the real world scenario, siloed document management software is likely to have an independent database from your ERP.

It would help if you had centralized access control that ERP document management provides to prevent disclosing your confidential documents because of unintended negligence.

3. Compliance

If you are in the space with requirements of document approvals or release control, your regulatory bodies may penalize you for oversight. The most common industries with such requirements include medical device, automotive, aerospace, defense, etc.

Along with the requirements of centralized control in the case of Sarbanes-Oxley (or SOX) compliance, you may need to have e-signature capabilities with some of your workflows.

This compliance overhead will add an unnecessary admin burden to your financial statements. An ERP document management system will help you comply with regulatory bodies easily without excessive overhead.

4. Traceability

Faster traceability improves customer experience, increases product margins, and enhances team morale. Let’s take an example of a customer experience. The quicker the resolution your customer service reps provide, the happier your customers will be. If you have siloed systems without a transactional correlation, it will take your representatives significantly longer to resolve issues.

The ERP document management system will provide end-to-end traceability of your customer interactions along with their related physical documents. This centralized view of your documents tied to customers and vendors records optimize your processes. And this optimization will result in better customer experience, reduced product cost, and superior employee experience.

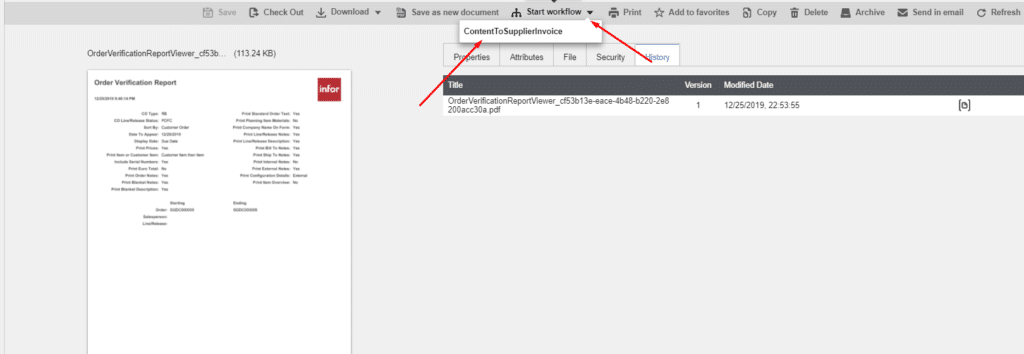

5. Workflow

A document could go through several stages in an organization as you make progress with its related transaction. For example, it could start with an opportunity, which may have a related quote document with line items. The follow-up documents may include design documents, marketing collaterals, packaging drawings, BOMs, or invoices.

These phases may include business rules where a document needs to go through a series of approvals before releasing it to the customer. The rules could comprise receiving an approved contract from the customer before you can kick-off your production or project.

In the case of standalone document management software, you will need to manage these workflows in several systems with manual, ad-hoc processes. The ERP document management system will include these workflows as part of the system.

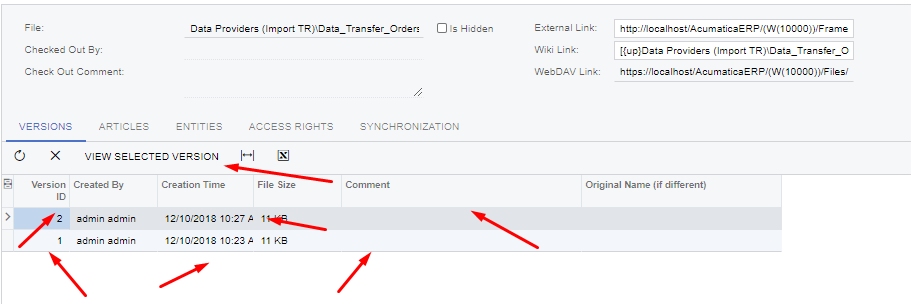

6. Document Change Management

As documents evolve with your processes, they could have several revisions. To ensure the usage of an intended version, you need to manage the version history. The inability to track versions or track changes could lead to conflicts in your teams, followed by chaos and blame.

To summarize, an ERP document management provides the ability to manage changes with features such as check-in, check-out, and changelogs.

Ten essential features of an ERP document management system

If you are in the process of evaluating a manufacturing ERP, you may want to review the following features that manufacturers commonly require.

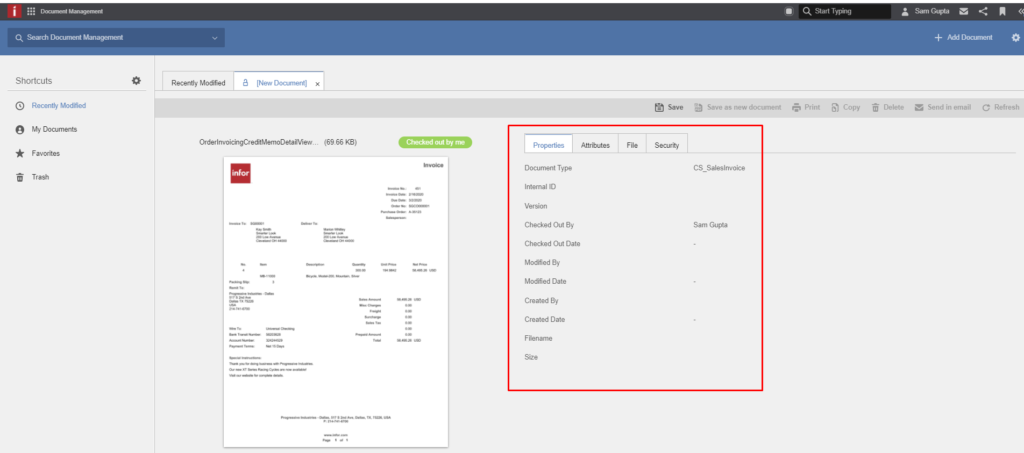

1. File Structure

Having support for different modes of searching for a file may not be as relevant if your file volume is low. However, once your file volume grows, you need sophisticated searching and filtering capabilities to search for documents through universal search.

While the universal search could provide excellent capabilities, not every user will be comfortable using it. Consequently, the system must support diverse organization and traceability capabilities. For instance, the users should be able to organize files in logical folders, but the search capabilities should not be tightly-coupled to this folder structure. Additionally, they should also be able to locate the file by going to the appropriate record and locate corresponding files.

2. Search

While most vendors may claim that they have sophisticated search capabilities, the enterprise system will support building complex criteria. With some learning curve initially, your team will be highly efficient once they get the hang of different options that the system supports.

For example, Google has several options that you could use in its search box. An ERP Document Management system will support similar possibilities.

3. Ease of Use

Ease of use could be a subjective topic. Your users will find a system easy-to-use that reduces the number of clicks in performing their document management duties.

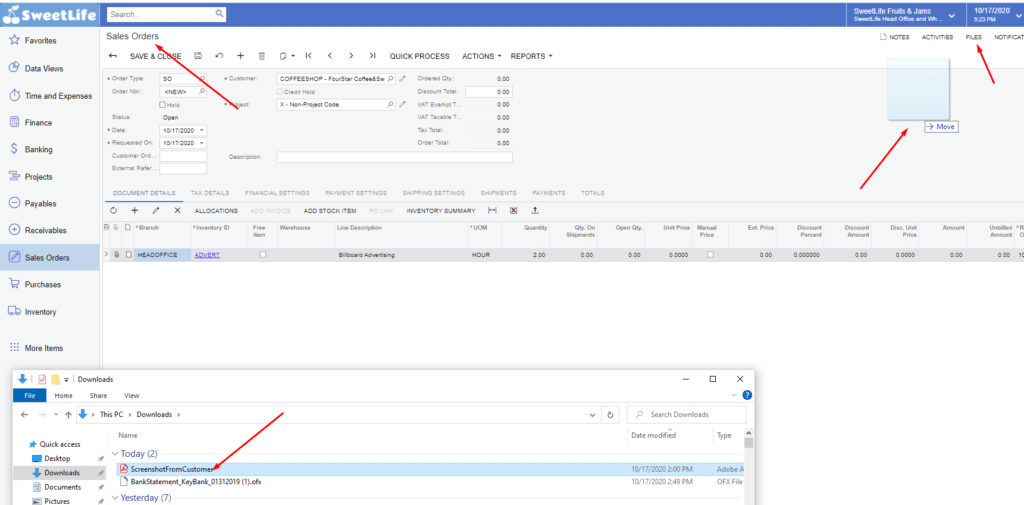

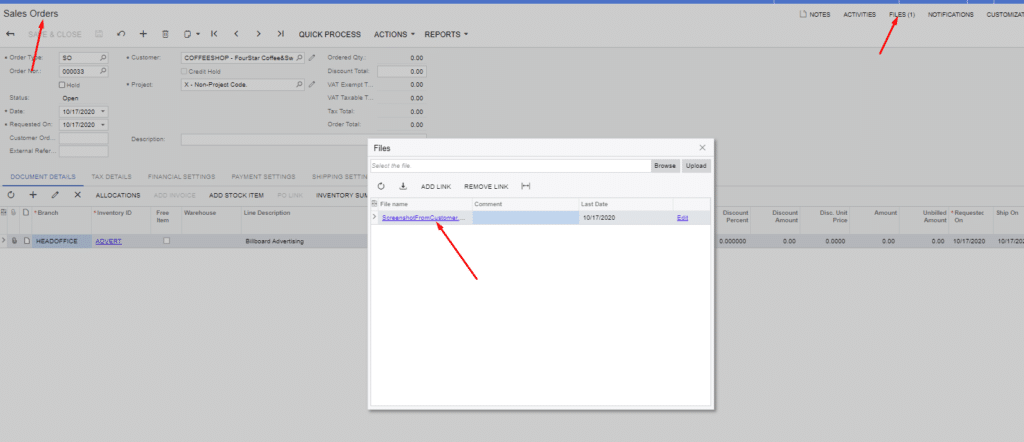

For example, Acumatica cloud ERP automatically creates the PDF version of different documents and attaches with the appropriate record. In the legacy ERP systems, the same process might require dozens of clicks and steps. Acumatica cloud ERP also allows you to drag and drop files on any transactions or records.

4. Mobile Access

Since they often need to quickly take pictures from their mobile devices and store them on appropriate records, your field sales and technicians need mobile capabilities.

Without these abilities, they might not remember to enter critical data in your ERP or might not use the system at all. Having robust mobile functionality ensures product adoption and marks your team efficient.

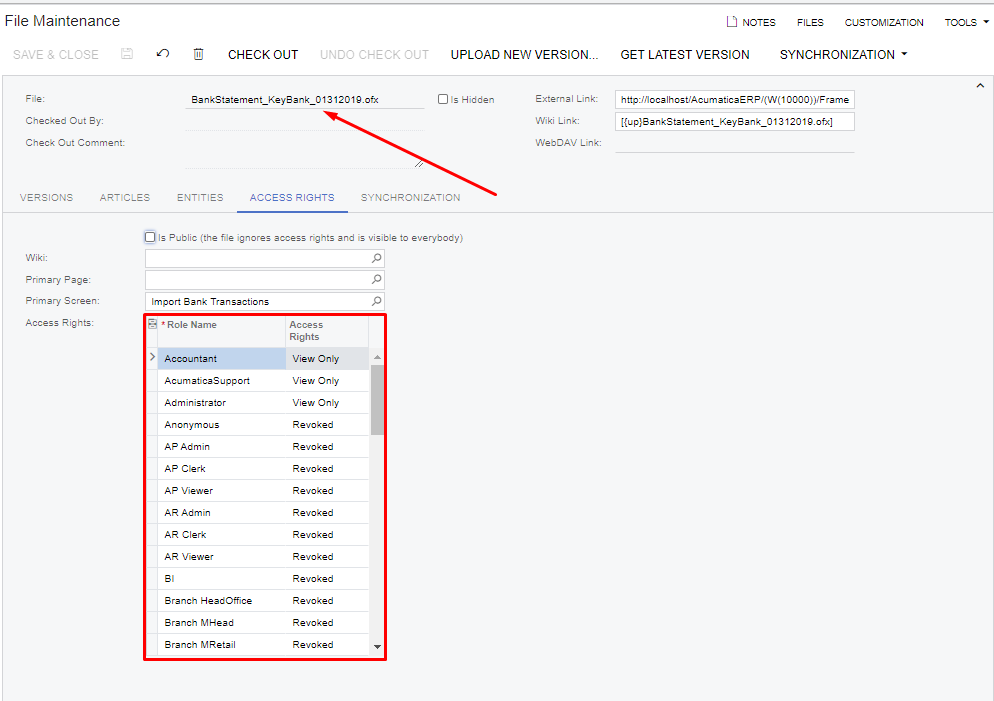

5. Security

Having appropriate security privileges for each role and user allows you to control the access of your documents. The access features must inherit security roles from your ERP so that you don’t have two sources of truth and security loopholes.

6. E-signature

You may need e-signature capabilities if you serve FDA-regulated customers to log the confirmations on training or compliance. If you are part of regulated industries, your compliance authorities may require you to have e-signature capabilities.

Having e-signature capabilities integrated as part of your document management software will help meet your compliance needs.

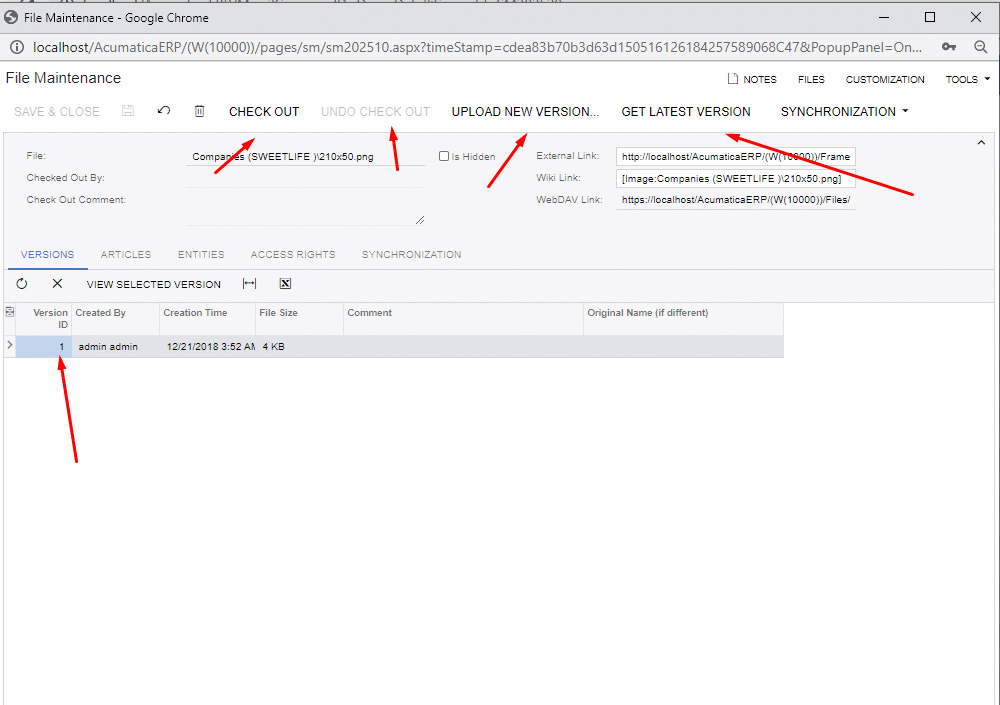

7. Version Control

While the processes such as Engineering Change Order (ECN) could provide you control over your BOM versions, your physical documents require version control capabilities.

First, the ability to check-out a document prevents other users from making changes simultaneously. Second, the check-in feature allows you to submit your changes while opening up for other team members to checkout. Finally, the rollout feature will enable you to roll back any changes while the audit trail provides the ability to review the changelog.

While features such as annotation and stamps are nice-to-have, some manufacturers may need them depending upon their collaboration complexity.

8. Workflow

As manufacturers become more sophisticated with their automation capabilities, the need for document-driven workflow will increase. A robust ERP document management system will allow you to develop business process workflows.

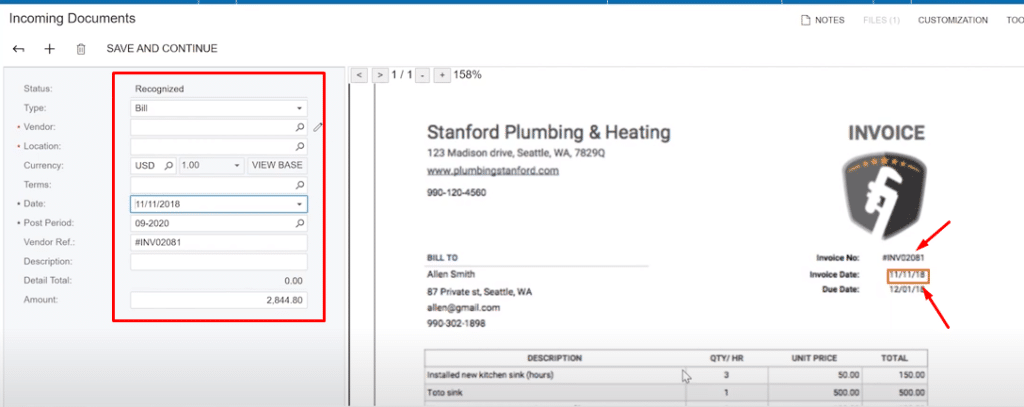

For example, upon saving the physical invoice in your document storage, you might want to kick off a log entry process to capture invoice details in another system. Complex workflows such as this will allow you to create document-driven business process workflows.

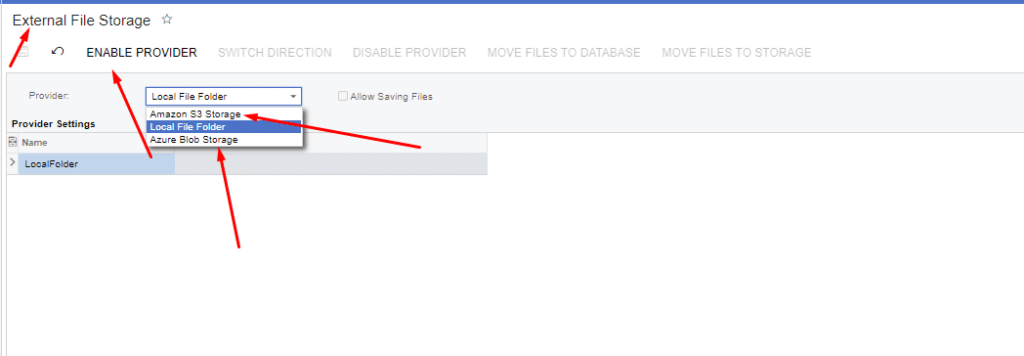

9. File Types Support

Manufacturers have complex needs when it comes to supporting different file types. If a document management software doesn’t support storing CAD design or packaging artwork, these teams may not use your ERP system. They might also use another method, creating two sources of truth.

The robust ERP document management system supports Blob and link storage while also allowing to interface with external storage. The support for external storage may be necessary as some systems use old technologies for their storage. These old technologies could be prohibitively expensive to store a large file base. The newer technologies might provide the same capabilities for the faction of costs.

A robust ERP document management system providers a variety of options for your storage while allowing you to control your storage costs.

10. Attribute level permissions

The Attribute level permission feature enables attributes to have a different security model compared to other attributes. That is to say, it adds another layer of access control and provides extended control on top of your role-based security.

For example, you might use this feature to control a “Status” attribute where only some can maintain its value. This feature allows granting access to users to edit some attributes but not the content of the document.

Conclusion

Inefficient document management processes can lead to severe inefficiencies with your operations. You need a robust electronic document management system (EDMS) to make your processes efficient.

ERP document management features provide robust capabilities for your enterprise-wide documentation needs while also meeting your compliance requirements. An efficient document management processes can lead to superior customer experience, higher profit margins, and improved employee morale.

If you have been experiencing the symptoms of blame games, conflicts, and churn in your team, you may be ready for an ERP system that provides robust document management capabilities.