Dynamics F&O vs Epicor Kinetic ERP Independent Review

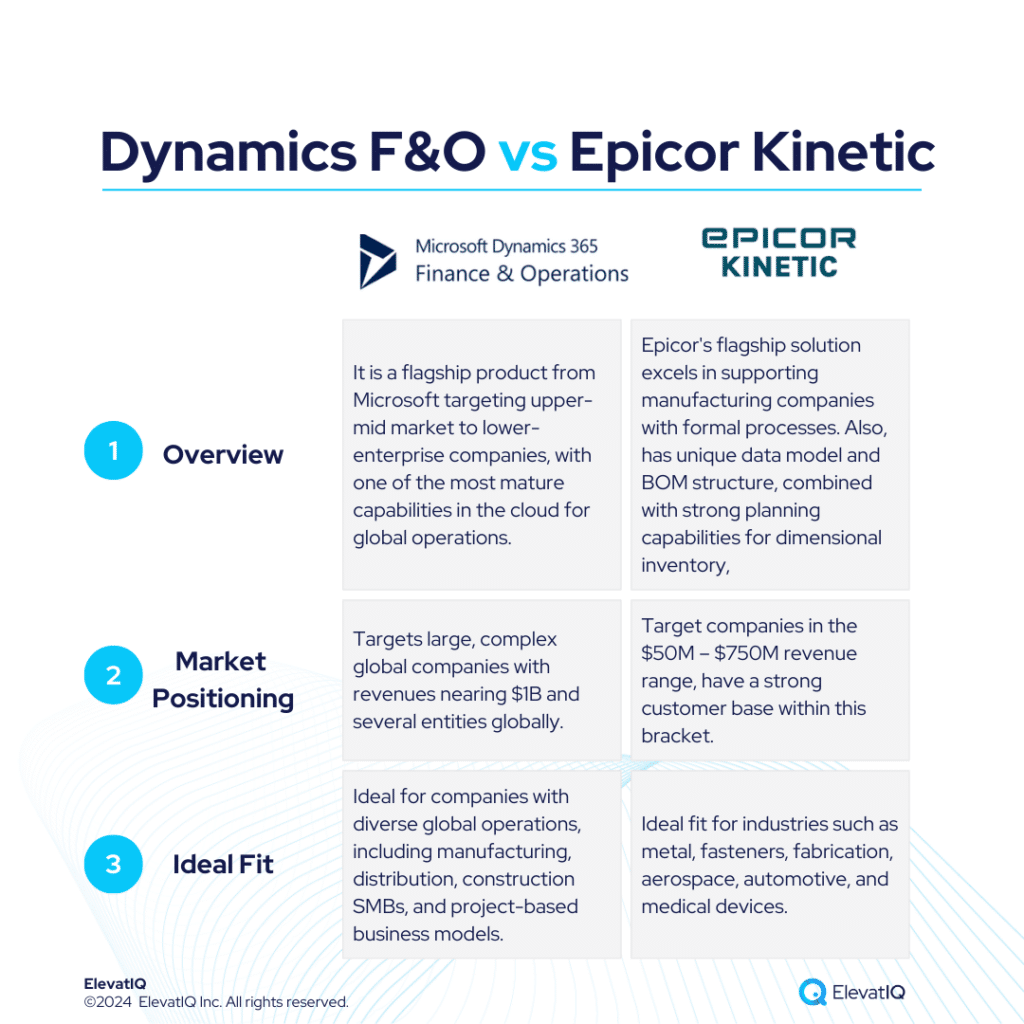

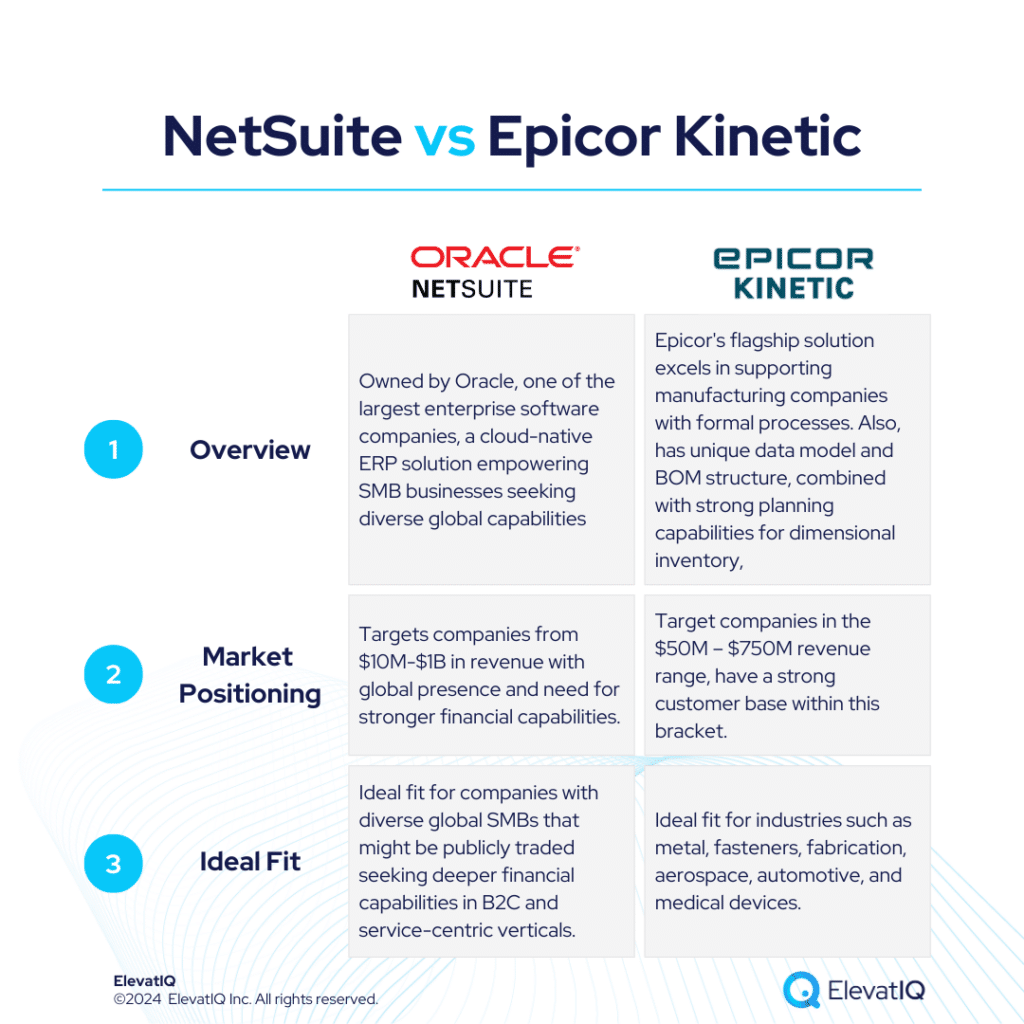

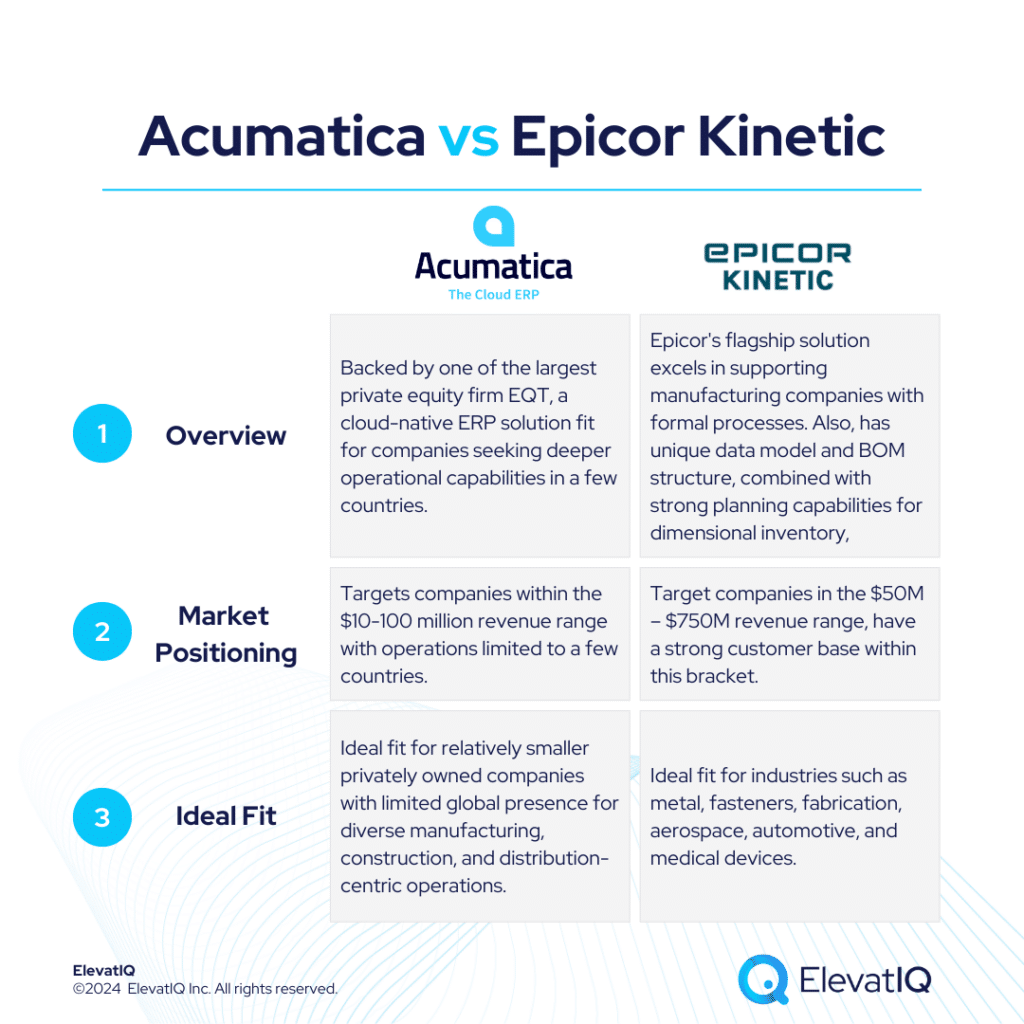

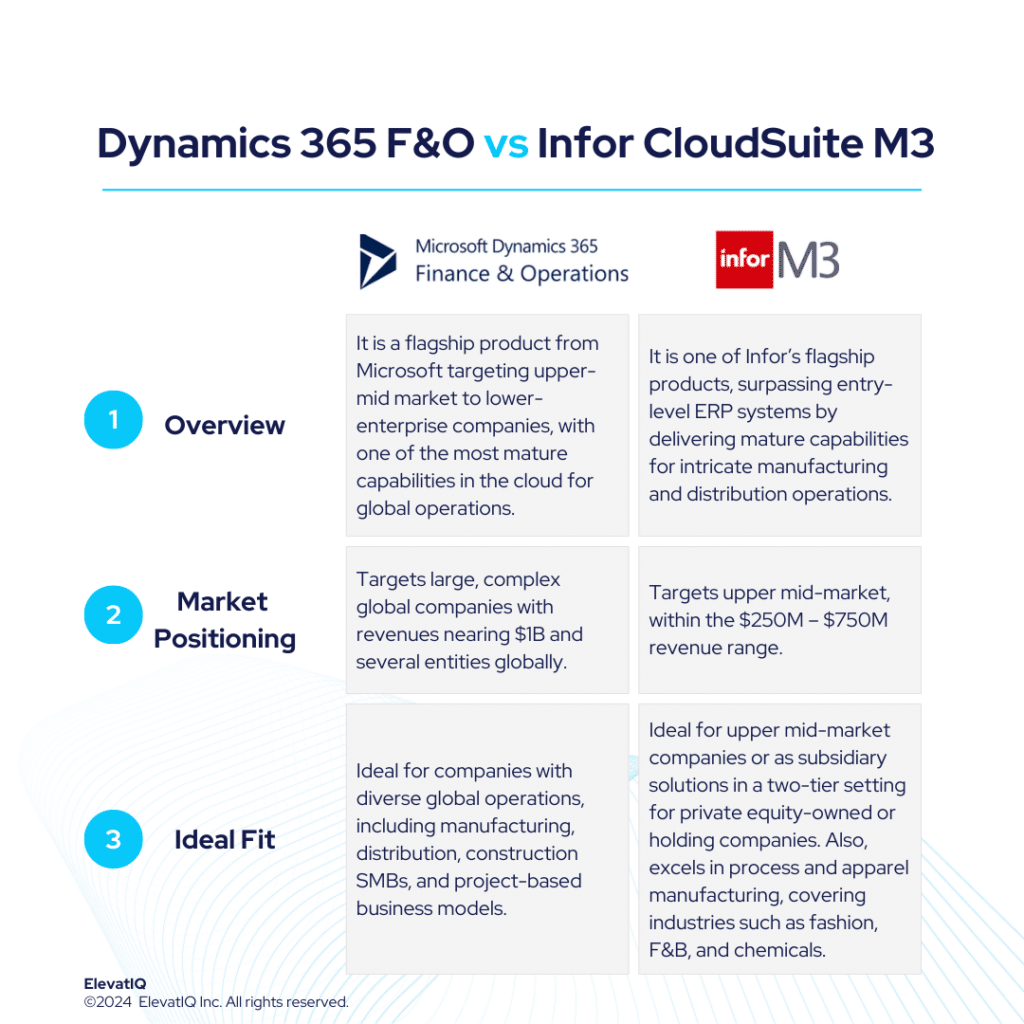

Microsoft Dynamics 365 F&O stands out for its enhanced cloud-native functionality, leading in capabilities over competitors like SAP S/4 HANA and Oracle Cloud ERP. It caters to large, global companies with complex business models, offering mature technology and a successful track record across industries. In contrast, Epicor Kinetic boasts a sophisticated data model, surpassing entry-level ERP systems like Acumatica or NetSuite. Dynamics F&O targets large, complex global companies with revenues nearing $1B and several entities globally. Whereas, Epicor Kinetic is positioned for companies in the $50M – $750M revenue range and it has a strong customer base within this bracket.

Dynamics 365 F&O is ideal for companies with diverse global entities, spanning industries like manufacturing, distribution, and construction. Whereas, Epicor Kinetic excels in catering to manufacturing companies with formal processes. Its distinctive data model and BOM structure, coupled with robust planning capabilities for dimensional inventory, make it ideal for industries like metal, fasteners, fabrication, aerospace, automotive, and medical devices.

However, navigating the Microsoft Dynamics 365 ecosystem may require assistance due to the presence of unqualified partners. Despite some technical issues, Dynamics F&O remains a solid choice for companies of varying sizes and models. On the other hand, Epicor Kinetic is tailored for companies advancing beyond basic transactional processing, it targets those in need of mature manufacturing capabilities such as MRP, allocation, and scheduling. Choosing between Dynamics F&O vs Epicor Kinetic requires a detailed examination, and this comparison offers valuable insights for ERP selection projects. Let’s delve deeper into the specifics.

| MS Dynamics 365 F&O | Epicor Kinetic | |

| Started in | One of the most established enterprise software companies in the world | Rebranding in 2021 (legacy version existed for more than 20 years) |

| Ownership by | Microsoft | CD&R, over $57B in assets, and CVC with over $220B in assets |

| No. of customers | 50,000+ | 23,000+ |

What is Microsoft Dynamics 365 Finance & Operations (F&O)?

Microsoft Dynamics 365 F&O is often the third choice for larger global accounts, following SAP S/4 HANA and Oracle Cloud ERP. It offers a mature ecosystem with modern, cloud-native technologies, thus proving successful across various industries. It is perhaps the most diverse solution accommodating several global business models in one database, making it an ideal solution particularly for lower enterprise companies. While a great fit as a corporate ledger for large enterprises, it’s not as proven as other leading solutions in the enterprise market with workloads as high as millions of journal entries per hour that Fortune 1000 companies might demand.

Microsoft Dynamics 365 F&O also excels in localizations where other solutions may falter. A vibrant ecosystem makes it suitable for private equity and also holding companies aiming to streamline their portfolio companies on one solution. SMBs, however, might find its complex data model overwhelming. Large, complex global companies with revenues exceeding $1B will particularly find Microsoft Dynamics 365 F&O appealing.

Although Microsoft Dynamics 365 F&O lacks the operational depth of specialized solutions, larger companies favor its corporate-level financial control. In a two-tier setting, they often particularly utilize additional Dynamics 365 F&O add-ons like Adeaca for operational requirements. Furthermore, Dynamics F&O offers seamless integration for field service, HCM, and CRM at the database level, empowering large companies to construct a best-of-breed architecture. It is especially strong with WBS-centric processes covering operational and financial schedules equally well. Hence, the challenge with MS Dynamics F&O would be the best-of-breed ancillary systems critical for A&D systems, which are not owned and maintained by Microsoft, requiring third-party add-ons.

What Is Epicor Kinetic?

Epicor Kinetic, their flagship solution, particularly excels in catering to manufacturing companies with formal processes. Its distinctive data model and BOM structure, coupled with robust planning capabilities for dimensional inventory, make it ideal for industries like metal, fasteners, fabrication, aerospace, automotive, and medical devices. Epicor Kinetic’s versatile data model addresses complex planning needs for companies particularly with diverse business models, encompassing manufacturing, distribution, and construction. Moreover, its advanced features support WBS-centric processes, enabling efficient management of large manufacturing programs with centralized cost tracking.

Epicor Kinetic boasts a sophisticated data model, surpassing entry-level ERP systems particularly like Acumatica or NetSuite. Tailored for companies advancing beyond basic transactional processing, it targets those in need of mature manufacturing capabilities such as MRP, allocation, and scheduling. Implementation success with Epicor Kinetic also requires substantial expertise in process and data coding, making it unsuitable for founder-led companies lacking seasoned operational and financial executives with ERP experience. Given its rigid revision model, companies with suboptimal SKU and BOM models may face challenges during implementation, emphasizing the need for robust internal capabilities and advisory support.

Epicor Kinetic has also undergone noteworthy technological advancements, adopting a look and feel reminiscent of Microsoft Dynamics ERP systems. Despite its legacy status, it supports mature cloud capabilities like enterprise search. Positioned for companies particularly in the $50M – $750M revenue range, it has a strong customer base within this bracket. Current limitations also include its field service capabilities, which are being addressed through an acquired add-on, and its finance and accounting module, not as tightly integrated as other modern cloud-native solutions.

Dynamics F&O vs Epicor Kinetic Comparison

Navigating the choice between Dynamics F&O vs Epicor Kinetic is a significant decision for businesses particularly looking for operational efficiency and strategic alignment. Thus, this section delves into the comprehensive comparison of Dynamics F&O vs Epicor Kinetic across various critical dimensions.

| MS Dynamics 365 F&O | Epicor Kinetic | |

| Global Operational Capabilities | Can host multiple entities from different countries. | The limited number of global and financial layers would require inefficient workarounds, particularly like using sub-accounts for traceability. |

| Diverse Capabilities | Can accommodate most business models, may require add-ons. | The versatile data model addresses complex planning needs for companies with diverse business models, including manufacturing, distribution, and construction. |

| Best-of-breed Capabilities | Crucial capabilities such as PLM, etc, may not be pre-integrated. | Limited, relying on third party add-ons for field service and quality module. |

| Last-mile Capabilities | May require add-ons for specific micro-verticals. | Pre-packaged capabilities for metal, automotive, and aerospace verticals. |

| Operational Functionalities | Rich operational functionality for large enterprises. | Equipped with strong mixed-mode manufacturing capabilities, and strong WBS-centric processes. |

| Integration Capabilities | Pre-integrated with CRM and field service. | With out-of-the-box MES functionality, particularly appeals to smaller companies seeking pre-integrated Industry 4.0 capabilities. |

| Manufacturing Capabilities | Mature capabilities support diverse models. | Manufacturing organizations with formal processes and revision numbers will relate more. |

| Pricing Model | Cost per user per month with flexible user management, without long-term commitment. | Per user, monthly. |

| Key Modules | 1. Financial Management 2. Supply Chain Management 3. Manufacturing Management 4. Human Capital Management 5. Business Intelligence and Reporting 6. Security and Compliance 7. Develop and Customize 8. System Administration | 1. Financial Management 2. Supply Chain Management 3. Production Management 4. Risk and Compliance 5. Customer Relationship Management 6. Project Management 7. Cloud Business Platform 8. Business Intelligence and Analytics 9. Planning and Scheduling 10. Services and Assets 11. Omnichannel Sales 12. Product Management 13. Global Business Management |

Dynamics F&O vs Epicor Kinetic Feature Comparison

Both platforms offer a plethora of features and functionalities designed to streamline business operations and enhance efficiency. In this feature comparison, we delve into particularly the distinct capabilities of Dynamics F&O vs Epicor Kinetic across various critical dimensions, providing insights to aid businesses in making informed decisions regarding their ERP selection. Thus, this section discusses features under each of the following modules, particularly financial management, supply chain management, and manufacturing management.

Financial Management Comparison

In this section, we are discussing a detailed comparison of the financial management capabilities particularly offered by Dynamics F&O vs Epicor Kinetic. By examining their respective strengths and functionalities, particularly in managing financial processes. Businesses can therefore gain valuable insights to determine the best-suited ERP solution for their financial management needs.

| MS Dynamics 365 F&O | Epicor Kinetic | ||

| Financial Management | General Ledger | Creates and maintains accurate records for financial transactions and generates regular financial reports. | It is a customizable, secure core component of its Financial Management suite. Offers accounting controls, seamless integration with other financial modules, global capabilities, and also advanced reporting tools. |

| Accounts Receivable and Accounts Payable | Automates workflows for managing vendor invoices, payments, and customer invoicing, streamlining the entire invoicing process and improving cash flow management. | Includes AR (managing invoicing, credit, cash, and customer payments) and AP (automating invoice processing, supporting multiple payment methods, and tracking expenses). | |

| Cash Flow Management | Provides comprehensive cash flow forecasting capabilities, allowing to project future cash positions, identify potential shortfalls, and make informed decisions. | Features automated cash handling, bank reconciliation, multi-currency and multi-bank management, integration with other financial modules, and also real-time reporting and analysis. | |

| Other Features | Chart of Accounts -Enables the creation of a hierarchical structure for categorizing financial information. | Currency Management – Simplifies multi-currency transactions, automates exchange rate management, integrates with other financial modules, ensures global compliance, and provides real-time reporting and analysis. | |

| Budgeting and Forecasting – Creates and manages budgets across different departments and business units. Also, leverages historical data and predictive analytics, to make accurate projections and align their financial strategies with business goals. | Tax Management – Automates sales and use tax calculations, integrates with financial modules, supports multiple jurisdictions, provides real-time updates, and simplifies reporting and filing. |

Supply Chain Management Comparison

In this comparison, we explore and analyze the supply chain management capabilities of Dynamics F&O vs Epicor Kinetic, shedding light particularly on their respective strengths and weaknesses.

| MS Dynamics 365 F&O | Epicor Kinetic | ||

| Supply Chain Management | Warehouse Management | Provides advanced warehouse and transportation management features, including inventory tracking, order fulfillment, shipment planning, and real-time visibility into logistics operations. | Optimizes operations with real-time inventory tracking, advanced material management, seamless integration with other systems, and configurable workflows. |

| Service Management | Establishes service agreements and service subscriptions, handles service orders and customer inquiries, and manages and analyzes the delivery of services to customers. | Streamlines operations with maintenance management, service contract handling, case management, RMA tracking, and real-time insights for efficient equipment upkeep and customer support. | |

| Inventory Management | Offers real-time visibility into inventory levels, demand, and supply, enabling organizations to optimize their inventory planning, reduce stockouts, and improve customer satisfaction. | Optimizes processes with detailed tracking, smart planning, advanced units of measure, automated purchase contracts, and seamless integration with supply chain and production modules. | |

| Other Features | Procurement and Sourcing – Streamlines the procurement process by providing end-to-end visibility and control over purchasing activities. Also automates and optimizes the procurement workflows, reducing costs and improving supplier relationships. | Purchase Order Management – Streamlines procurement with tools for supplier negotiations, order tracking, automated processes, and supplier relationship management. | |

| Transportation Management – Offers real-time visibility into logistics operations. | Sales Order Management – Streamlines sales with features for order tracking, automation, estimating, cross-functional collaboration, and eCommerce integration. | ||

| Demand Planning and Forecasting – Generates accurate demand forecasts, helping organizations optimize production planning, inventory levels, and procurement decisions. | Requisition Management – Automates procurement with real-time budget checks, vendor support, standing and blanket orders, multi-level approvals, and effective expenditure management. |

Manufacturing Management Comparison

In this comparison, we explore and analyze the manufacturing management capabilities of Dynamics F&O vs Epicor Kinetic, shedding light, particularly on their respective strengths and weaknesses.

| MS Dynamics 365 F&O | Epicor Kinetic | ||

| Manufacturing Management | Production Planning | Provides comprehensive production planning and control capabilities, allowing organizations to optimize their manufacturing processes. The system supports various production scenarios, including make-to-order, make-to-stock, and engineer-to-order, while providing real-time visibility into production schedules, resource allocation, and material requirements. | Enhances manufacturing efficiency with Master Production Scheduling, Material Requirements Planning, Advanced Planning and Scheduling, Job Management, Lean Manufacturing, Quality Management, and Advanced MES for real-time monitoring. |

| Other Features | Shop Floor Management – Offers real-time monitoring of shop floor activities, capturing data on machine utilization, labor productivity, and production progress. | BOM and Routing – Streamlines production with multi-level BOM management, dynamic BOM creation, CAD and PLM integration, strong change control, centralized routing management, detailed routing steps, real-time adjustments, and precise cost and time estimation. | |

| Product Lifecycle Management – Enables organizations to manage the entire product lifecycle, from design and engineering to manufacturing and after-sales service. The system integrates product data, engineering change orders, and quality management processes, ensuring seamless collaboration and visibility across different departments. | Advanced Planning and Scheduling – Enhances production efficiency with automated scheduling, flexible capacity planning, real-time adjustments, what-if scenarios, integrated material constraints, and multi-site management. |

Pros of Dynamics F&O vs Epicor Kinetic

When evaluating ERP solutions, understanding the distinct advantages of Dynamics F&O vs Epicor Kinetic is crucial. In this section, we are particularly exploring the strengths of Dynamics F&O vs Epicor Kinetic across various dimensions. Thus, shedding light on their respective capabilities and functionalities.

| MS Dynamics 365 F&O | Epicor Kinetic |

| Has a significant advantage in its extensive consulting base and a vibrant marketplace, a unique benefit unmatched by many ERP systems. | Epicor has a very similar look and feel to Microsoft ERP products, providing you with the same experience but with much deeper last-mile capabilities. |

| Supports global operations and business models and pre-baked integration for the best-of-breed CRM and field service solutions. | 90% of the capabilities required by verticals such as metal, automotive, and aerospace are pre-packaged with the core platform. |

| Embedded WMS and TMS processes help companies that might require end-to-end traceability even after the good leaves the dock. | Great fit for manufacturing organizations that follow formal manufacturing processes with revision numbers. |

| Legacy product rearchitected for the cloud. So, while better than other legacy products that might be behind in the cloud. | Although a legacy product, it includes mature cloud capabilities such as enterprise search and transactional maps for end-to-end transactional traceability. |

Cons of Dynamics F&O vs Epicor Kinetic

Just like recognizing strengths is important, it’s also crucial to weigh the specific drawbacks of Dynamics F&O vs Epicor Kinetic. Therefore, in this section, we will delve into the limitations and challenges associated with Dynamics F&O vs Epicor Kinetic across various operational and financial dimensions.

| MS Dynamics 365 F&O | Epicor Kinetic |

| Overwhelming for smaller companies with the configuration and approval flows built for large enterprises. | The data layers are highly detailed, requiring substantial consulting help to be successful with the product. |

| Might not be able to match the performance expectations of larger organizations where processing millions of journal entries per hour is required. | The limited focus on certain business models poses the risk of requiring other ERP systems to support complex and diverse business operations. |

| Overbloated financial control processes, such as compliance, allocation, and approval flows, which are only necessary for large organizations. | The field service capabilities are not as embedded and proven as some of the other products. |

| May require consulting assistance to navigate the channel, given the presence of unqualified ISVs and VARs. | Epicor takes a suite approach to its products while selling directly to its customers. This limits the overall consulting and marketplace penetration. |

| Integration with A&D-specific PLMs, configurators, and CPQ systems is not out-of-the-box, increasing the implementation time and costs. | Requires ad-hoc arrangements for larger mid-market companies with more than three financial hierarchies. |

| The last-mile capabilities for specific A&D verticals, such as integration with GovCon processes and databases, may require solutions from third parties or custom integration, making the implementation overly expensive. | Finance and accounting layers are not going to be as strong as some of the other products. |

Conclusion

In conclusion, in the case of Dynamics F&O vs Epicor Kinetic, both offer robust ERP solutions, but they cater to different segments of the market with unique strengths. Dynamics F&O is also a comprehensive solution ideal for large, complex global companies with revenues approaching $1 billion. It excels in providing mature cloud-native capabilities, extensive global localization, and also a broad ecosystem that supports various business models, from manufacturing to distribution. However, its complexity and the need for add-ons may pose challenges for smaller companies or those requiring specific operational functionalities.

On the other hand, Epicor Kinetic is a powerful choice for mid-market companies, particularly in the manufacturing sector. Its advanced data model, strong planning capabilities, and industry-specific features make it an excellent fit for industries particularly like aerospace, automotive, and metal fabrication. While it lacks the global reach and extensive marketplace of Dynamics F&O, Epicor Kinetic’s focus on formal manufacturing processes and last-mile capabilities provides significant value for companies within its target market.

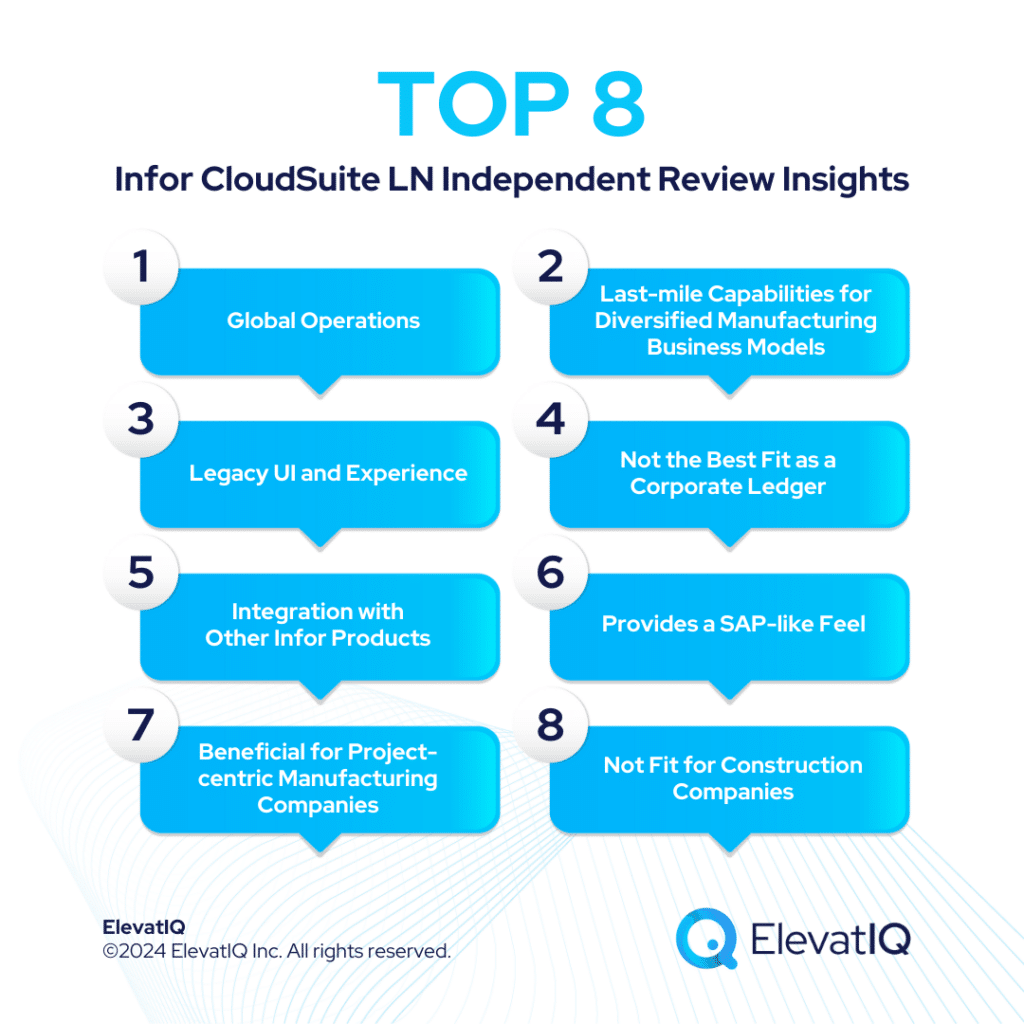

Both systems have their strengths and limitations, so businesses should carefully evaluate their specific needs and growth aspirations to determine the most suitable ERP solution. Also, seeking assistance from an independent ERP consultant can significantly aid the decision-making process. To get a 360-degree view of feature comparisons, it’s essential to explore not only Dynamics F&O vs. Epicor Kinetic but also insights from other analyses such as Dynamics F&O vs.SAP S/4 HANA, Acumatica, Oracle Cloud ERP, NetSuite, MS Dynamics 365 BC, Infor CloudSuite LN, and Infor CloudSuite M3.

FAQs

Dynamics F&O vs Epicor Kinetic ERP Independent Review Read More »