NetSuite vs Epicor Kinetic ERP Independent Review

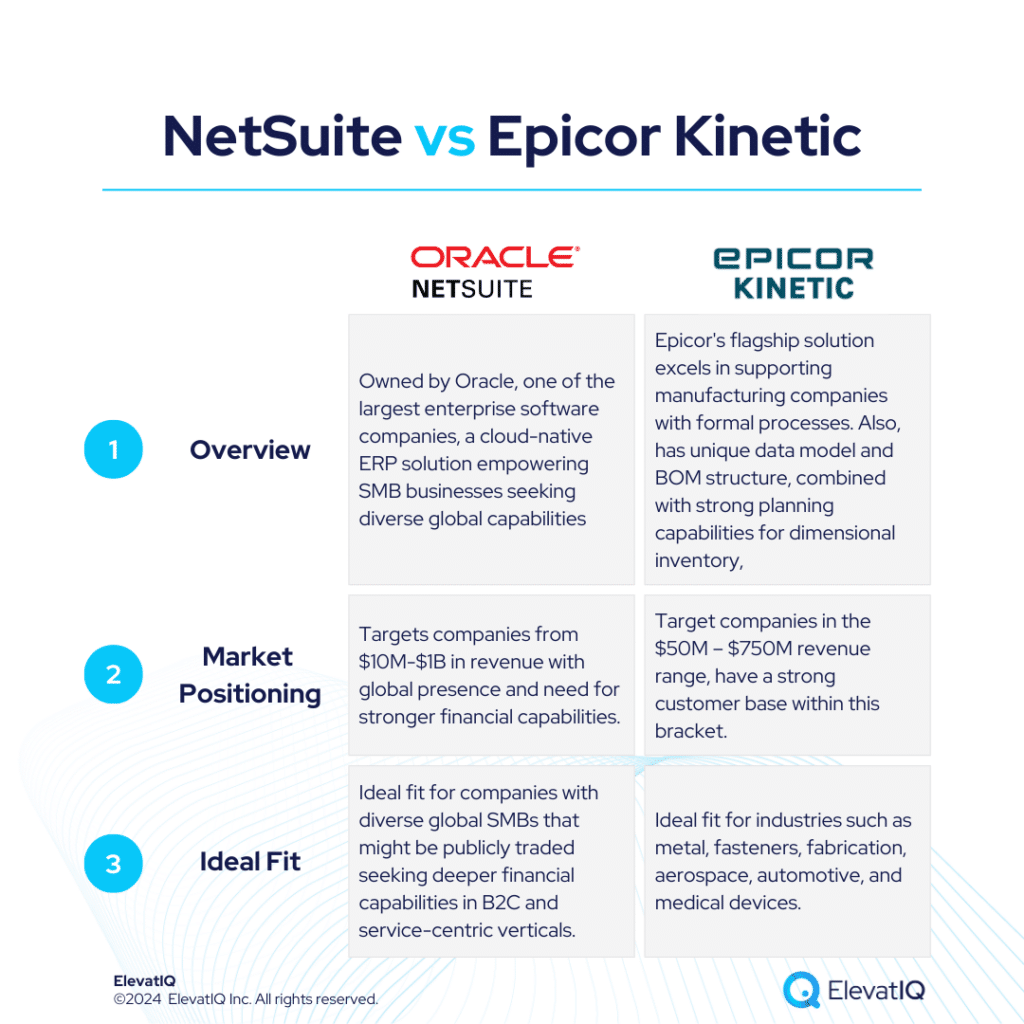

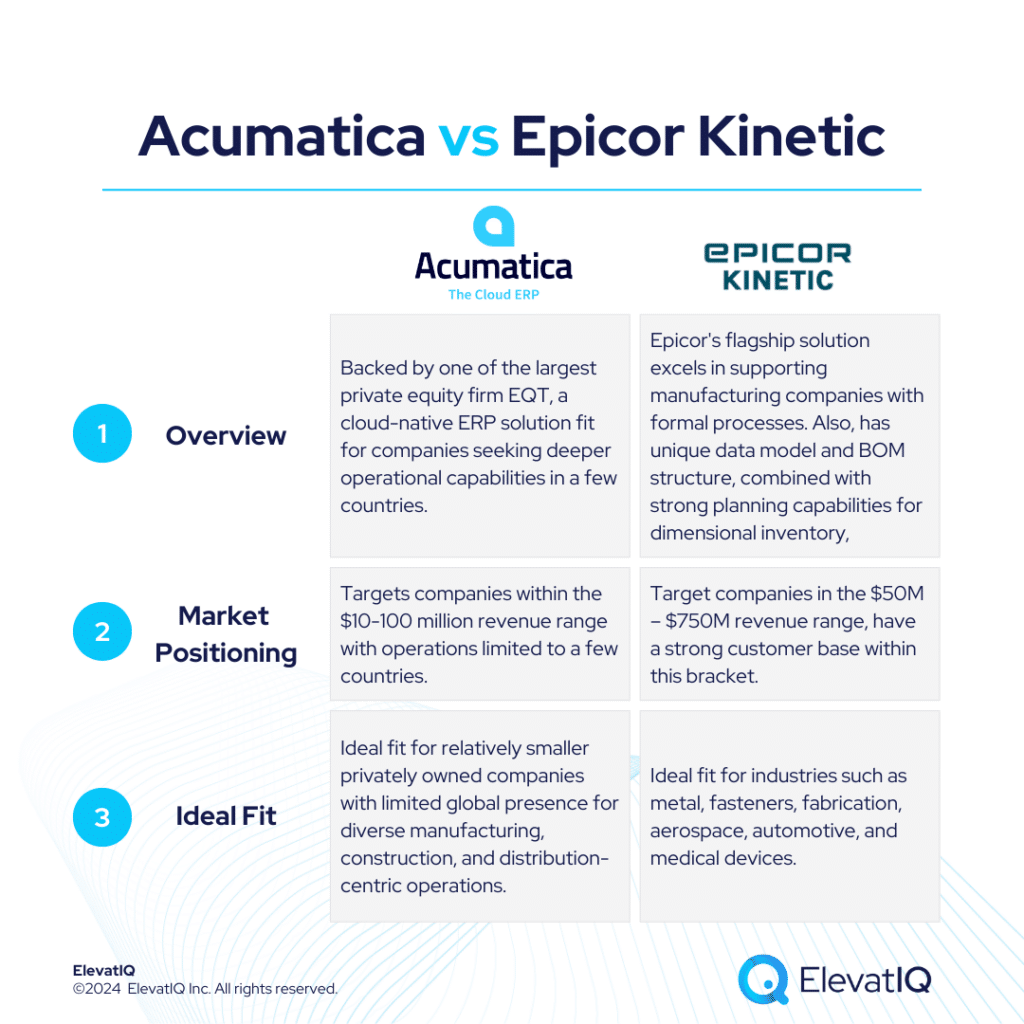

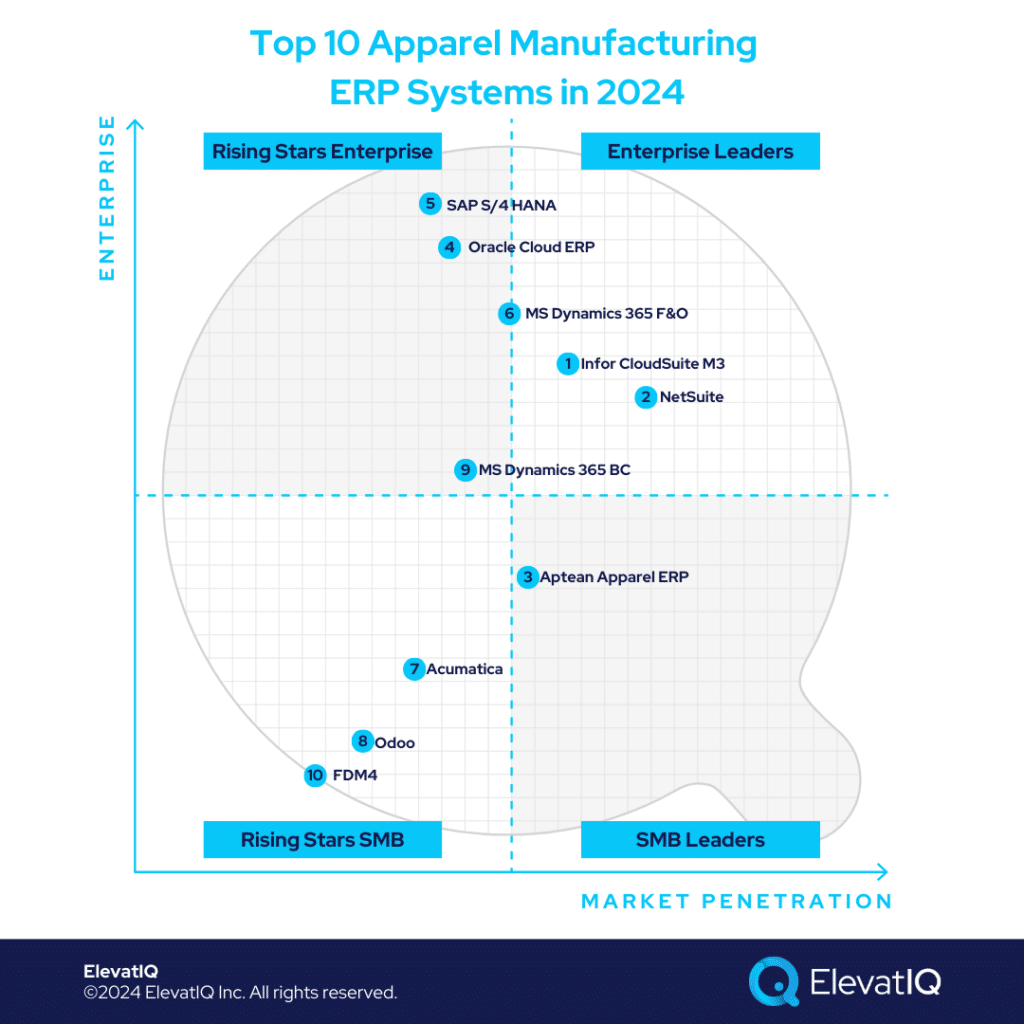

Epicor Kinetic, surpasses entry-level ERP systems like Acumatica or NetSuite. On the other hand, NetSuite caters well to globally spread small to mid-market companies seeking robust financial capabilities with localization in numerous countries. Epicor Kinetic is positioned for companies in the $50M – $750M revenue range and it has a strong customer base within this bracket. Whereas, NetSuite targets companies from $10M-$1B in revenue with global presence and need for stronger financial capabilities.

Epicor Kinetic excels in catering to manufacturing companies with formal processes. Its distinctive data model and BOM structure, coupled with robust planning capabilities for dimensional inventory, make it ideal for industries like metal, fasteners, fabrication, aerospace, automotive, and medical devices. Conversely, NetSuite is suitable for a diverse range of companies, including service-centric, distribution-centric, commerce-centric, and B2C organizations. It also performs well across various industries but may lack depth for industrial distributors and manufacturers, focusing more on lighter manufacturing and consumerized products like health and beauty, fashion, apparel, and CPG.

Epicor Kinetic is also tailored for companies advancing beyond basic transactional processing, it targets those in need of mature manufacturing capabilities such as MRP, allocation, and scheduling. Whereas, with robust financial capabilities and an integrated HCM solution, NetSuite is well-suited for service-centric industries, including smaller banks, credit unions, financial services, non-profit organizations, as well as the technology and media sectors. Choosing between NetSuite vs Epicor Kinetic requires a detailed examination, and this comparison offers valuable insights for ERP selection projects. Let’s delve deeper into the specifics.

| NetSuite | Epicor Kinetic | |

| Started in | 1998 | Rebranding in 2021 (legacy version existed for more than 20 years) |

| Ownership by | Oracle in 2016 | CD&R, over $57B in assets, potentially selling to a new buyer soon |

| No. of customers | 37,000+ | 23,000+ |

What is NetSuite?

NetSuite stands out as the leading ERP solution, driven by its success particularly for diverse industries seeking stronger financial capabilities over the operational, robust ecosystem, credible marketplace add-ons, and comprehensive functionality. Not as complex as some competitors like SAP S/4 HANA and Microsoft F&O, NetSuite also excels in supporting diverse business models, including omnichannel architecture, matrix/dimensional inventory, and subscription-based models.

While NetSuite excels across industries, it may not be the ideal choice for industrial distributors and manufacturers due to limitations in pricing and item master capabilities. Its strength lies in supporting lighter manufacturing and also consumerized products like health and beauty, fashion, apparel, and CPG. With robust financial capabilities and an integrated HCM solution, NetSuite is well-suited for service-centric industries, including smaller banks, credit unions, financial services, non-profit organizations, as well as the technology and media sectors.

While NetSuite remains the top-ranked solution due to its product quality, there might be challenges with over-customization and integration issues, leading to implementation failures. Working with NetSuite demands thorough vetting of their solution and architecture.

What Is Epicor Kinetic?

Epicor Kinetic, their flagship solution, particularly excels in catering to manufacturing companies with formal processes. Its distinctive data model and BOM structure, coupled with robust planning capabilities for dimensional inventory, make it ideal for industries like metal, fasteners, fabrication, aerospace, automotive, and medical devices. Epicor Kinetic’s versatile data model addresses complex planning needs for companies particularly with diverse business models, encompassing manufacturing, distribution, and construction. Moreover, its advanced features support WBS-centric processes, enabling efficient management of large manufacturing programs with centralized cost tracking.

Epicor Kinetic boasts a sophisticated data model, surpassing entry-level ERP systems particularly like Acumatica or NetSuite. Tailored for companies advancing beyond basic transactional processing, it targets those in need of mature manufacturing capabilities such as MRP, allocation, and scheduling. Implementation success with Epicor Kinetic also requires substantial expertise in process and data coding, making it unsuitable for founder-led companies lacking seasoned operational and financial executives with ERP experience. Given its rigid revision model, companies with suboptimal SKU and BOM models may face challenges during implementation, emphasizing the need for robust internal capabilities and advisory support.

Epicor Kinetic has also undergone noteworthy technological advancements, adopting a look and feel reminiscent of Microsoft Dynamics ERP systems. Despite its legacy status, it supports mature cloud capabilities like enterprise search. Positioned for companies particularly in the $50M – $750M revenue range, it has a strong customer base within this bracket. Current limitations also include its field service capabilities, which are being addressed through an acquired add-on, and its finance and accounting module, not as tightly integrated as other modern cloud-native solutions.

NetSuite vs Epicor Kinetic Comparison

Navigating the choice between NetSuite vs Epicor Kinetic is a significant decision for businesses particularly looking for operational efficiency and strategic alignment. Thus, this section delves into the comprehensive comparison of NetSuite vs Epicor Kinetic across various critical dimensions.

| NetSuite | Epicor Kinetic | |

| Global Operational Capabilities | Natively localized in over 100 countries. | The limited number of global and financial layers would require inefficient workarounds, particularly like using sub-accounts for traceability. |

| Diverse Capabilities | Supports diverse business models across multiple countries. | The versatile data model addresses complex planning needs for companies with diverse business models, including manufacturing, distribution, and construction. |

| Best-of-breed Capabilities | Contains pre-integrated components like HCM and FP&A, though the maturity of these components may vary. | Limited, relying on third party add-ons for field service and quality module. |

| Last-mile Capabilities | Limited last-mile capabilities, especially for manufacturing. | Pre-packaged capabilities for metal, automotive, and aerospace verticals. |

| Operational Functionalities | Richer financial capabilities over operational features. | Equipped with strong mixed-mode manufacturing capabilities, and strong WBS-centric processes. |

| Integration Capabilities | Offers several pre-integrated solutions with more options from Celigo. | With out-of-the-box MES functionality, appeals to smaller companies seeking pre-integrated Industry 4.0 capabilities. |

| Manufacturing Capabilities | Limited BOM layers for assembly-centric operations, requiring additional add-ons. | Manufacturing organizations with formal processes and revision numbers will relate more. |

| Pricing Model | Named-user based with inflexible long-term contracts. | Per user, monthly. |

| Key Modules | 1. Financial Management 2. Accounting 3. Global Business Management 4. Inventory Management 5. Order Management 6. Supply Chain Management 7. Warehouse Management 8. Procurement 9. Customer Relationship Management | 1. Financial Management 2. Supply Chain Management 3. Production Management 4. Risk and Compliance 5. Customer Relationship Management 6. Project Management 7. Cloud Business Platform 8. Business Intelligence and Analytics 9. Planning and Scheduling 10. Services and Assets 11. Omnichannel Sales 12. Product Management 13. Global Business Management |

NetSuite vs Epicor Kinetic Feature Comparison

Both platforms offer a plethora of features and functionalities designed to streamline business operations and enhance efficiency. In this feature comparison, we delve into particularly the distinct capabilities of NetSuite vs Epicor Kinetic across various critical dimensions, providing insights to aid businesses in making informed decisions regarding their ERP selection. Thus, this section discusses features under each of the following modules, particularly financial management, and supply chain management.

Financial Management Comparison

In this section, we are discussing a detailed comparison of the financial management capabilities particularly offered by NetSuite vs Epicor Kinetic. By examining their respective strengths and functionalities, particularly in managing financial processes. Businesses can therefore gain valuable insights to determine the best-suited ERP solution for their financial management needs.

| NetSuite | Epicor Kinetic | ||

| Financial Management | General Ledger | Supports complex general ledgers including public reporting requirements of several countries. | It is a customizable, secure core component of its Financial Management suite. Offers accounting controls, seamless integration with other financial modules, global capabilities, and also advanced reporting tools. |

| Accounts Receivable and Accounts Payable | Automates and streamlines invoice delivery, payment processing, and collections management as well as accounts payable processes. | Includes AR (managing invoicing, credit, cash, and customer payments) and AP (automating invoice processing, supporting multiple payment methods, and tracking expenses). | |

| Cash Flow Management | Provides visibility to optimize cash flows, monitor bank accounts, and manage liquidity. | Features automated cash handling, bank reconciliation, multi-currency and multi-bank management, integration with other financial modules, and real-time reporting and analysis. | |

| Tax Management | Manages domestic and global tax, generates detailed reports, and analyzes transactions real-time. | Automates sales and use tax calculations, integrates with financial modules, supports multiple jurisdictions, provides real-time updates, and simplifies reporting and filing. |

Supply Chain Management Comparison

In this comparison, we explore and analyze the supply chain management capabilities of NetSuite vs Epicor Kinetic, shedding light particularly on their respective strengths and weaknesses.

| NetSuite | Epicor Kinetic | ||

| Supply Chain Management | Warehouse Management | Provides the ability to optimize day-to-day warehouse operations, eliminate manual processes and minimize handling costs. | Optimizes operations with real-time inventory tracking, advanced material management, seamless integration with other systems, and configurable workflows. |

| Service Management | Automates inventory management processes with multi-location fulfilment, cycle counting, replenishment, traceability and item visibility. | Streamlines operations with maintenance management, service contract handling, case management, RMA tracking, and real-time insights for efficient equipment upkeep and customer support. | |

| Inventory Management | Provides the ability to optimize day-to-day warehouse operations, eliminate manual processes and minimize handling costs. | Optimizes processes with detailed tracking, smart planning, advanced units of measure, automated purchase contracts, and seamless integration with supply chain and production modules. | |

| Procurement | Streamlines procurement processes with source management, purchase management, vendor management and invoice processing. | Streamlines procurement with tools for supplier negotiations, order tracking, automated processes, and supplier relationship management. | |

| Other Features | Supply Chain Planning – Provides the ability to analyze demand, determine replenishment requirements, add stock and create orders according to an up-to-date supply plan. | Purchase Order Management – Streamlines procurement with tools for supplier negotiations, order tracking, automated processes, and supplier relationship management. | |

| Supply Chain Execution– Optimizes all supply chain assets, controls costs at each step. | Sales Order Management – Streamlines sales with features for order tracking, automation, estimating, cross-functional collaboration, and eCommerce integration. |

Pros of NetSuite vs Epicor Kinetic

When evaluating ERP solutions, understanding the distinct advantages of NetSuite vs Epicor Kinetic is crucial. In this section, we are particularly exploring the strengths of NetSuite vs Epicor Kinetic across various dimensions. Thus, shedding light on their respective capabilities and functionalities.

| NetSuite | Epicor Kinetic |

| Provides richer financial capabilities over operational, with leaner operational layers built with the product compared to Epicor Kinetic. | Epicor has a very similar look and feel to Microsoft ERP products, providing you with the same experience but with much deeper last-mile capabilities. |

| Ideal for SMBs operating in different countries. | 90% of the capabilities required by verticals such as metal, automotive, and aerospace are pre-packaged with the core platform. |

| The data model is B2C friendly, supporting integration with B2C channels. | Great fit for manufacturing organizations that follow formal manufacturing processes with revision numbers. |

| Ideal for eCommerce-centric SMBs because of the ecosystem and the integration operations available for eCommerce-centric companies. | Although a legacy product, it includes mature cloud capabilities such as enterprise search and transactional maps for end-to-end transactional traceability. |

Cons of NetSuite vs Epicor Kinetic

Just like recognizing strengths is important, it’s also crucial to weigh the specific drawbacks of NetSuite vs Epicor Kinetic. Therefore, in this section, we will delve into the limitations and challenges associated with NetSuite vs Epicor Kinetic across various operational and financial dimensions.

| NetSuite | Epicor Kinetic |

| Not a great value for companies operating only in a few countries. | The data layers are highly detailed, requiring substantial consulting help to be successful with the product. |

| May struggle with transactional workload requirements of companies over $1B and the ones that might be acquiring 10-20 entities every year. | The limited focus on certain business models poses the risk of requiring other ERP systems to support complex and diverse business operations. |

| Not ideal for startups with simpler operating models. | The field service capabilities are not as embedded and proven as some of the other products. |

| Named-user-based pricing requires allocating fixed costs, even for seasonal workers or external users accessing the subset of data such as customer or vendor portals. | Epicor takes a suite approach to its products while selling directly to its customers. This limits the overall consulting and marketplace penetration. |

| Not fit for companies seeking OEM-owned integration with core operational systems such as CAD or PLM. | Requires ad-hoc arrangements for larger mid-market companies with more than three financial hierarchies. |

| The last-mile capabilities required for manufacturing or industrial distribution are extremely limited. | Finance and accounting layers are not going to be as strong as some of the other products. |

Conclusion

In conclusion, NetSuite vs Epicor Kinetic present compelling options for businesses seeking ERP solutions, but they cater to different needs and industries. NetSuite shines in its ability to support diverse global SMBs, particularly those in service-centric, distribution-centric, and B2C verticals, offering robust financial capabilities and a strong ecosystem of integrated solutions. Its flexibility makes it an ideal choice particularly for companies operating across multiple countries with complex financial reporting needs. However, NetSuite may fall short in handling the intricacies of industrial distribution and manufacturing, especially for businesses requiring deep operational capabilities.

On the other hand, Epicor Kinetic is tailored for manufacturing companies with formal processes, excelling in industries like metal, fasteners, aerospace, and automotive. Its advanced data model and strong planning capabilities make it a powerful tool for companies with complex manufacturing needs, particularly those within the $50M – $750M revenue range. While it may lack the global reach and financial depth of NetSuite, Epicor Kinetic offers superior last-mile capabilities for specific industries.

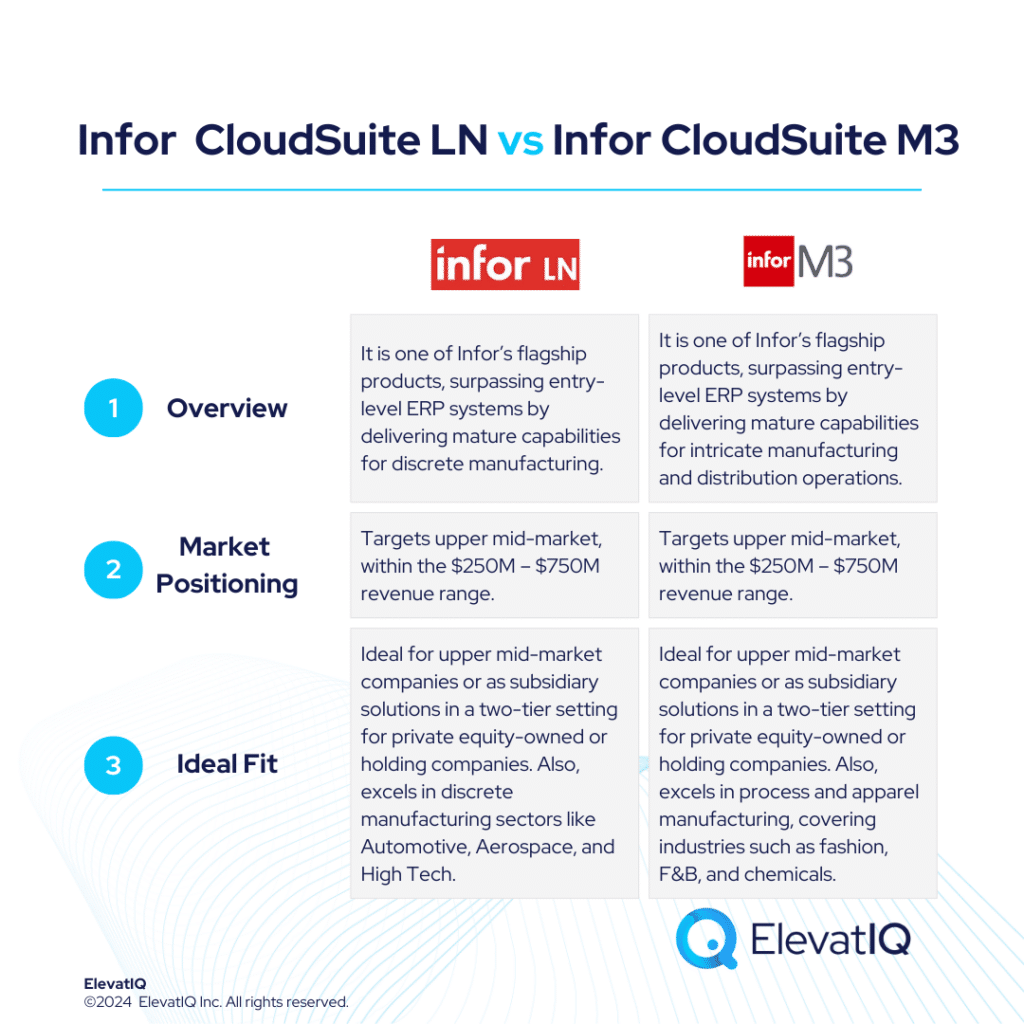

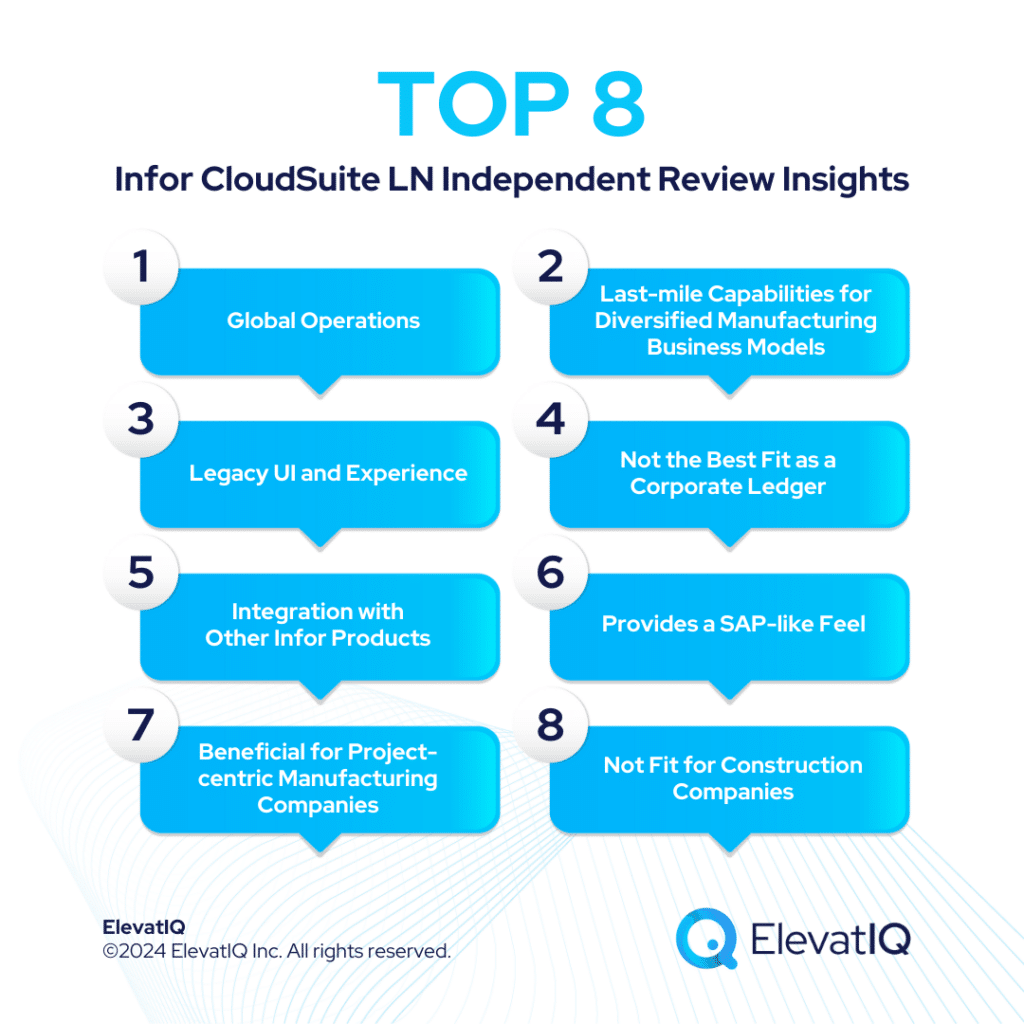

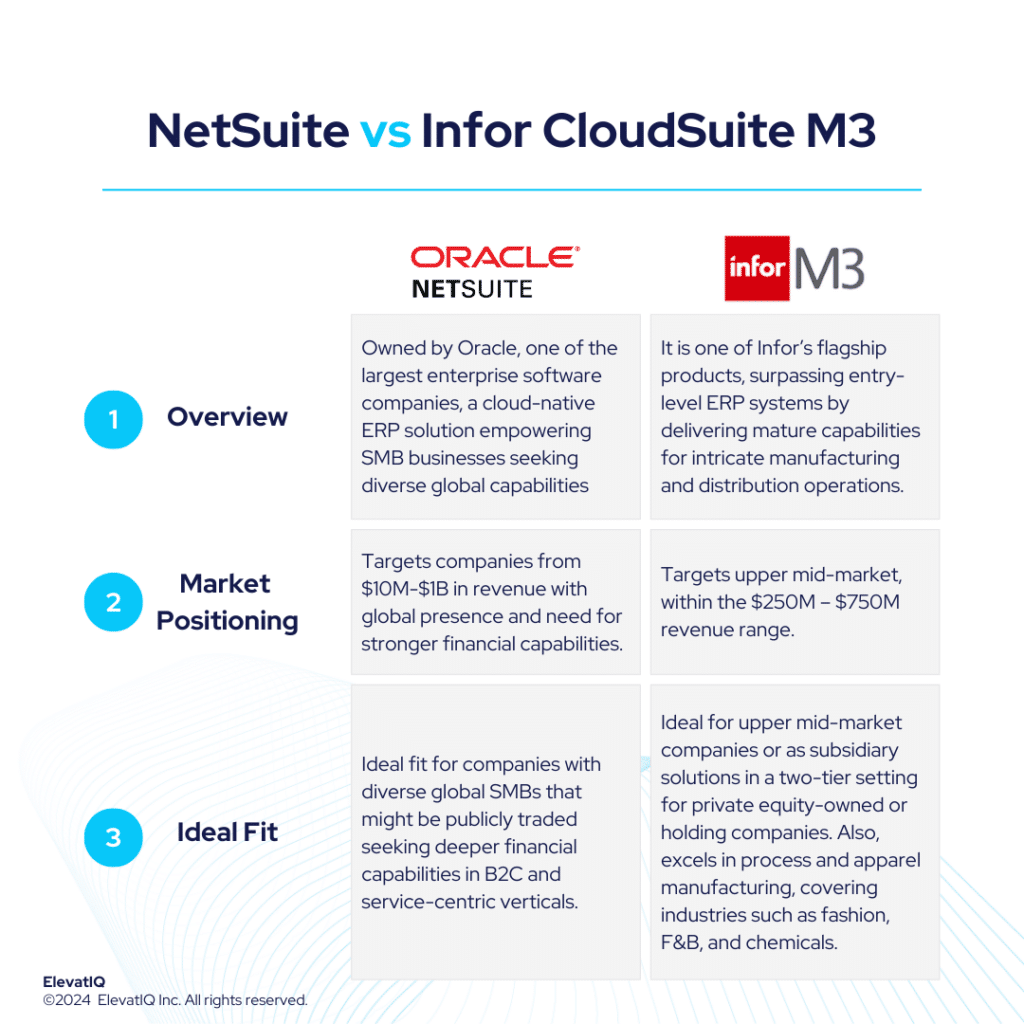

Choosing between these two ERP solutions requires a careful assessment of a company’s specific operational demands and also long-term growth strategies. Also, seeking assistance from an independent ERP consultant can significantly aid the decision-making process. To get a 360-degree view of feature comparisons, it’s essential to explore not only NetSuite vs. Epicor Kinetic but also insights from other analyses such as NetSuite vs. SAP S/4 HANA, Acumatica, Oracle Cloud ERP, MS Dynamics 365 F&O, MS Dynamics 365 BC, Infor CloudSuite LN, and Infor CloudSuite M3.

FAQs

NetSuite vs Epicor Kinetic ERP Independent Review Read More »